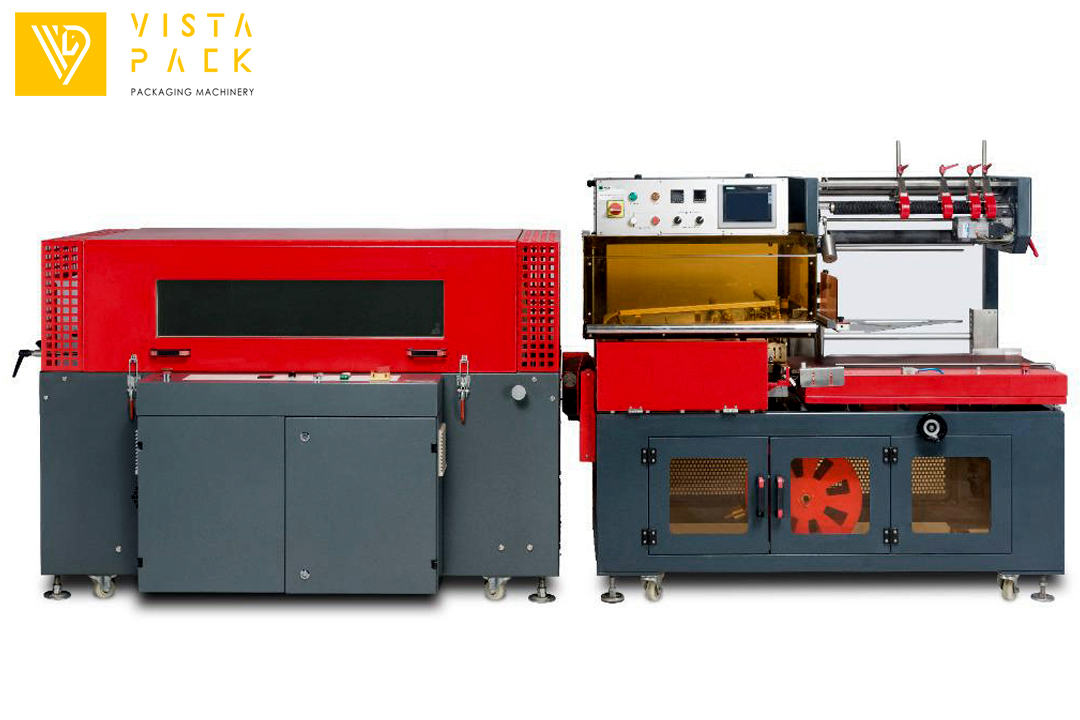

Automatic strapping machine is the key to success in modern packaging

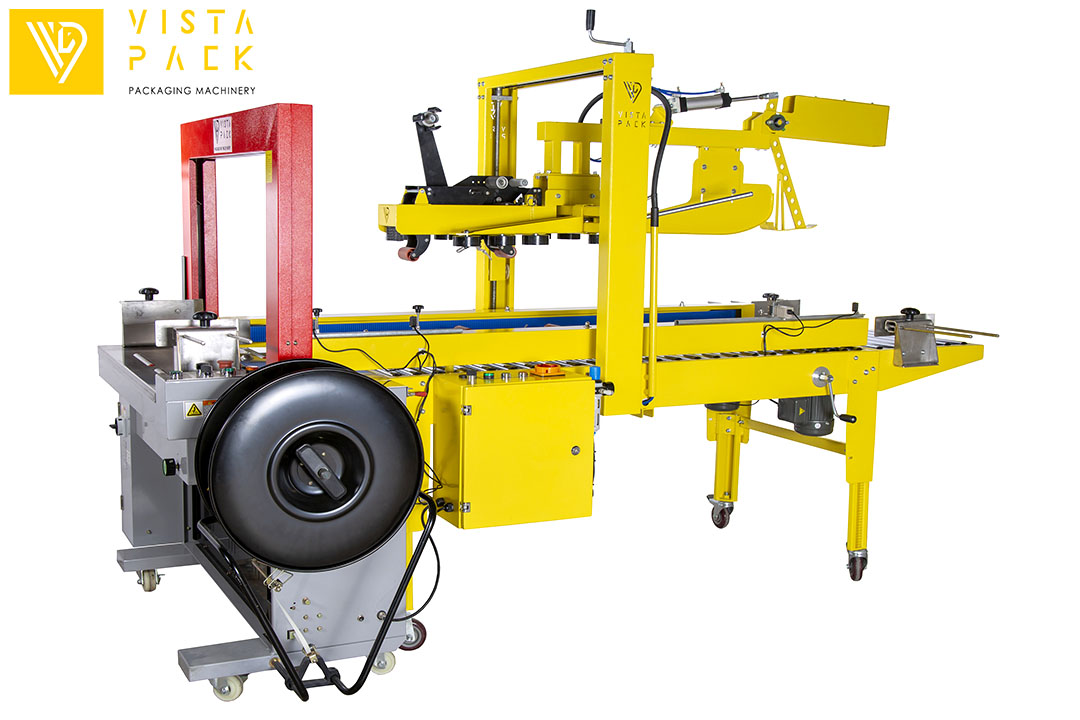

Automatic side seal or gate strapping machine is a smart choice for fast, safe and efficient packing and strapping. With its unique features, this device helps improve the performance of production lines and reduces costs.

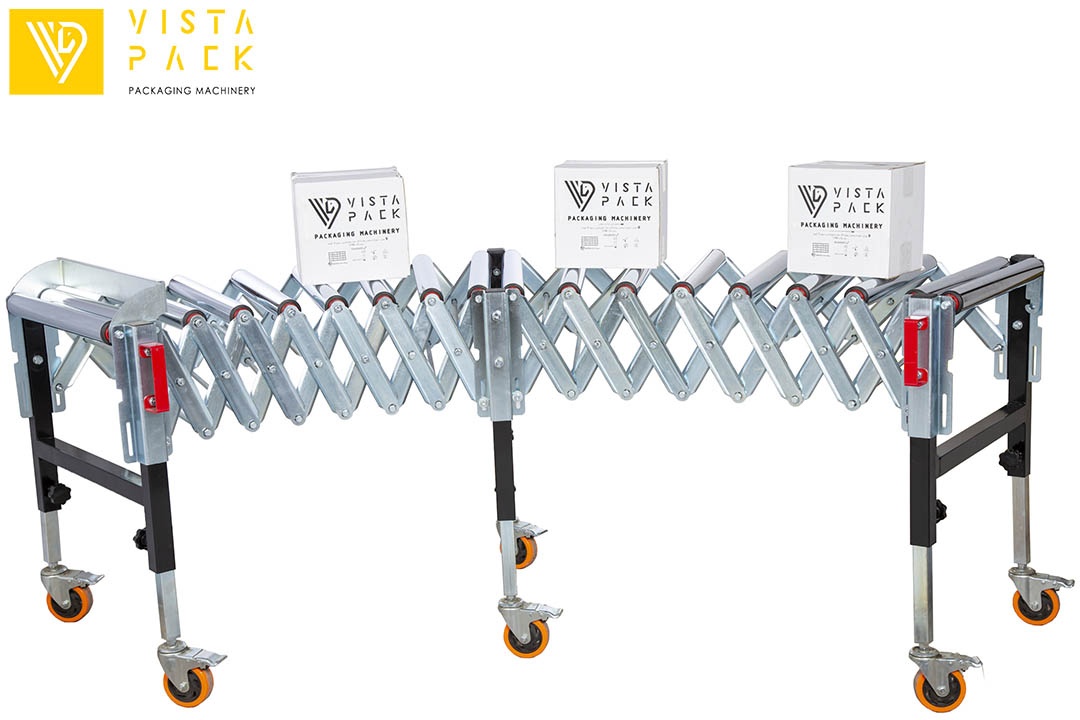

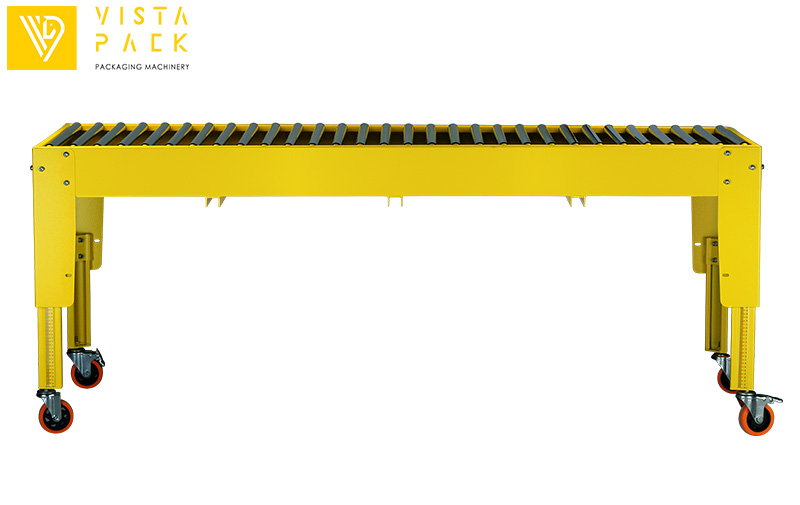

As an important part of the production chain, the packaging industry plays an essential role in increasing productivity, reducing damage to products, and optimizing the transportation process. Strapping machines have created a great revolution in packaging methods.

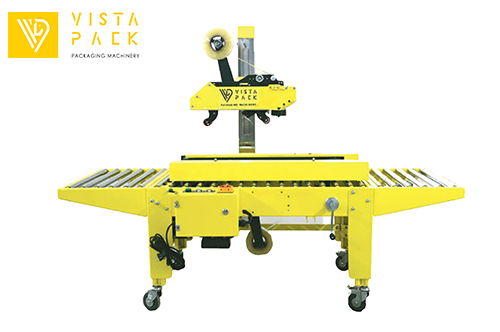

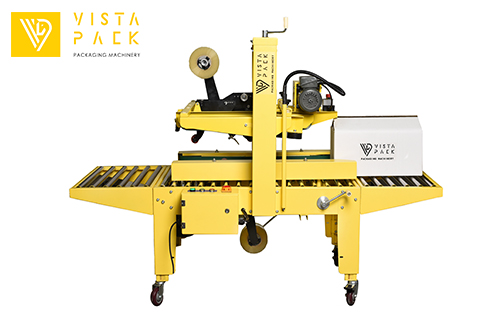

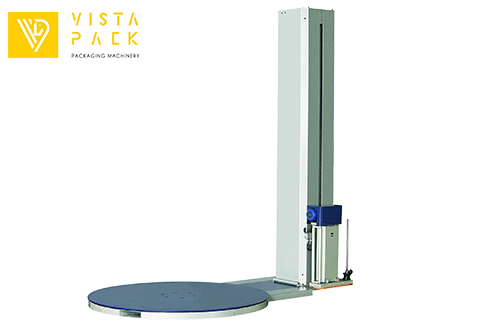

Automatic strapping machine from the side of Vista Pack

The sewing belt tensioner is ordered from Side Seal according to the dimensions and specifications of your product. This device is suitable for various types of household appliances, including gas and water conditioners, televisions, refrigerators, gas stoves, washing machines and dishwashers.

If you are looking for a modern and efficient equipment, the sewing machine from Vista Pack will be a unique option for you.

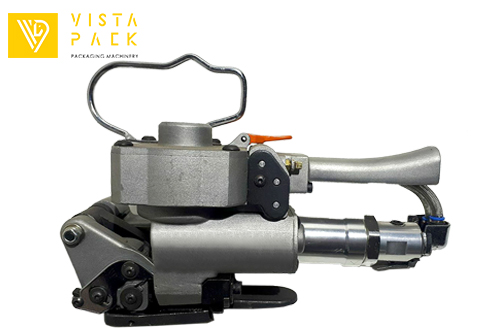

Free consultation with the number 📞00989123798626 to choose a manual belt tensioner suitable for your needs

Advantages of automatic strapping machine

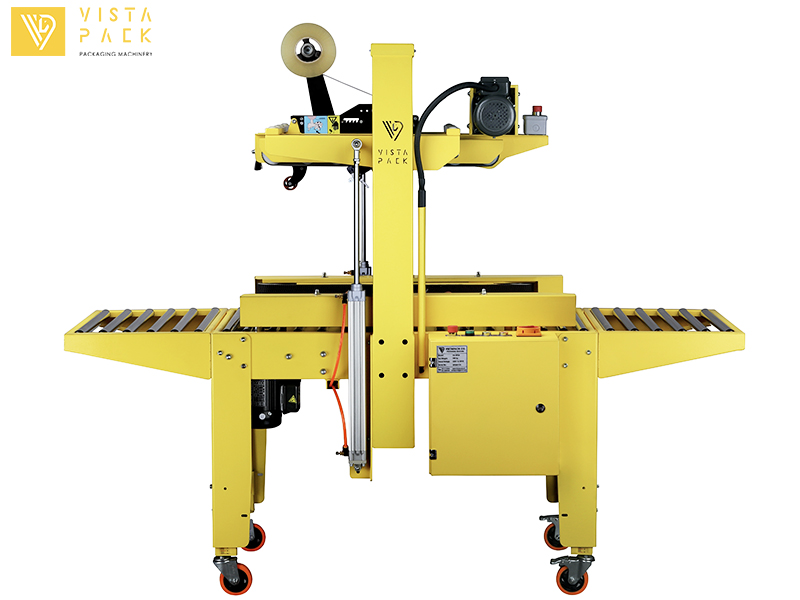

1️⃣Durable structure: The body of the device is made of stainless steel, which has high resistance to corrosion and moisture.

2️⃣Flexibility in the type of belt: it has the ability to use different types of belts with polypropylene PP and polyethylene terephthalate (PET) and in different widths and thicknesses.

3️⃣Advanced technology: the device has the ability to connect to intelligent management systems of production lines.

4️⃣Automatic and intelligent operation: digital control panels allow precise adjustment of the device. The machine is equipped with automatic systems for adjusting the speed, tension and cutting of the belt.

5️⃣High speed: the machine has the ability to strap 40 packages per minute. This will reduce downtime in production lines.

6️⃣High safety: the device’s automatic troubleshooting system minimizes the risk of human errors. Also, a safety lock is installed to prevent accidents when working with the device.

7️⃣Compatibility with industrial environments: The device with its ergonomic and industrial design is suitable for use in busy workshops and high-speed production lines.

📐Specifications of automatic belt tensioner for side seal gates | |

| Arc size of the device: can be ordered according to the product | Available device arc size: height 140cm * width 1000cm |

| Function: sewing from the side | Machine weight: 255Kg |

| Used belt size: 10mm ~ 12mm | Power consumption: VA 850 per hour |

| Belting speed: 2.5 seconds for each belt | Input power: single phase 220V |

Features of the side seal belt tensioner

Increasing the productivity of production lines: Due to its high speed and automatic operation, this device reduces the need for manpower and increases productivity.

Ensuring the security of packaging: the products packed by this device have high strength and the possibility of damage during transportation is minimized. Also,

strapping operations increase the quality of product packaging.

Reduced operating costs: By optimizing belt consumption and reducing the need for repairs, overall packaging costs are dramatically reduced.Continuous and uniform

performance during all working hours: You can use this device without interruption in different work shifts.

Environmental Support: Using recyclable belts such as PET makes the side seal belt tensioner an environmentally friendly option.

Applications of automatic strapping machine

1️⃣Food industry: This machine is used in packing all kinds of food cartons, canning boxes and pallets of perishable products.

2️⃣Pharmaceutical and medical industries: The side seal device is used to package sensitive pharmaceutical products, such as drugs and medical equipment.

3️⃣Petrochemical and chemical industries: It is used in packing heavy pallets of chemicals and petrochemical products.

4️⃣Electronics industries: strapping of electronic equipment is to protect these products from impact and transport damage.

5️⃣Automotive industry: It is suitable for packing heavy and large car parts for ease of transportation and storage.

Gate automatic belt tensioner💪Innovative solution for packaging

How automatic side sewing belt tensioner works

The method of working with automatic gate belt tensioner is very easy and does not require specialized training. In order to carry out the strapping operation, the product or goods first enters the gate, then by pressing the start button, the operation is done automatically.

⚡What are the differences between Vistapack semi-automatic and automatic gate belt tensioners?

Below you will learn about the differences between semi-automatic and automatic belt machines.

Features | Semi-automatic belt tensioner | Automatic belt tensioner |

| speed | average | up |

| Accuracy in belt tension | average | very high |

| safety | average | up |

| Maintenance cost | up | average |

| Need an operator | does not have | has |

| The cost of purchasing the device | suitable | up |

| The ability to link to the production line | does not have | has |

| Ark | does not have | has |

⚙️Periodic maintenance and service of strapping machine

Daily inspection of traction system

Monthly lubrication of moving parts

Periodic replacement of consumable parts

Regular calibration of sensors

Buying guide for side seal strapping machine

Below we will mention the important factors in choosing an automatic belt tensioner.

Checking the capacity of daily production lines

Dimensions and weight of products

Type of work environment (industrial, food, pharmaceutical)

Budget and maintenance costs

Attention to warranty and after-sales service

Choose a reliable brand

When you buy from Vista Pack, you’re not just buying a product – you’re choosing a complete experience of quality and satisfaction. Join our thousands of satisfied customers and feel the difference! To order or get more information, contact us now.

Side seal automatic strapping machine🚀the latest model with high tensile strength

- Food and canning industries

- Home appliances (air conditioners, televisions, refrigerators)

- Pharmaceutical and medical industries

- Petrochemical industries

- Automotive and electronic parts

Yes, according to customer needs

The machine is compatible with a variety of polypropylene (PP) and polyethylene terephthalate (PET) straps in widths of 10 to 12 mm.

Yes! The use of recyclable PET straps and reduced waste make this device an environmentally friendly option.

About 10-15% of the price of the device

No! The machine is very easy to use. Just insert the product into the gate and press the start button – the rest is done automatically.

An automatic machine has higher speed, accuracy, and safety, but it costs more to purchase. Its advantages include the ability to connect to a production line and the absence of the need for an operator.

The automatic side seal strapping machine is an advanced equipment for fast and safe packaging of goods that operates without the need for an operator and straps products with high quality.

The machine is capable of strapping 40 packages per minute and 2.5 seconds per strap, which significantly increases the productivity of production lines.

The device operates on 220V single-phase electricity and its power consumption is 850 VA per hour.

- One-year parts and performance warranty

- 10-year after-sales service

- Technical support and rapid supply of spare parts

Usually 2-3 business days

🔧 Support and after-sales service of Vista Pack

One year parts and performance warranty

10-year after-sales service

Technical support and fast supply of spare parts

Contact and more information to buy strapping machine

Contact number 📞00989123798626

Comments and suggestions

Dear user🖌 please help us in providing better services by registering your comments and suggestions regarding VISTA PACK packaging machines.

Ema –

📞 How can I get free advice?

Vista Pack –

For a free consultation and to choose the best device to suit your needs, call 00989123798626.