Vista Pack Packaging Industries

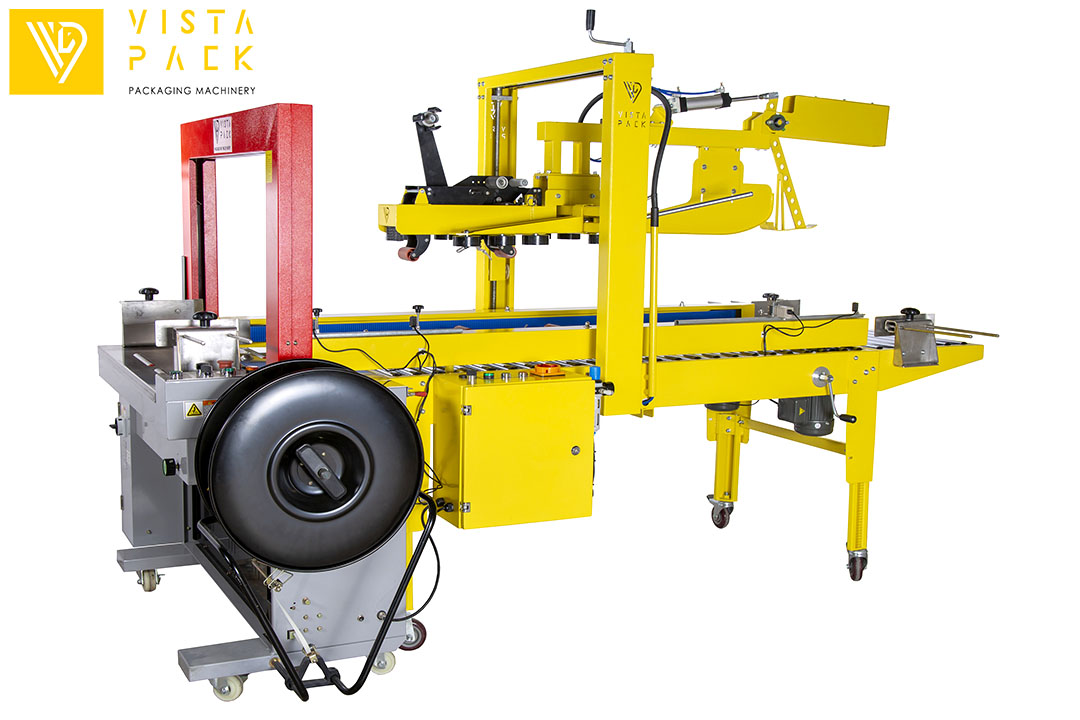

automatic strapping machine is a solution to increase the life of the equipment Are you looking for a way to increase speed and efficiency in your production line? The automatic strapping machine is a suitable answer to this need! Easy-to-use…

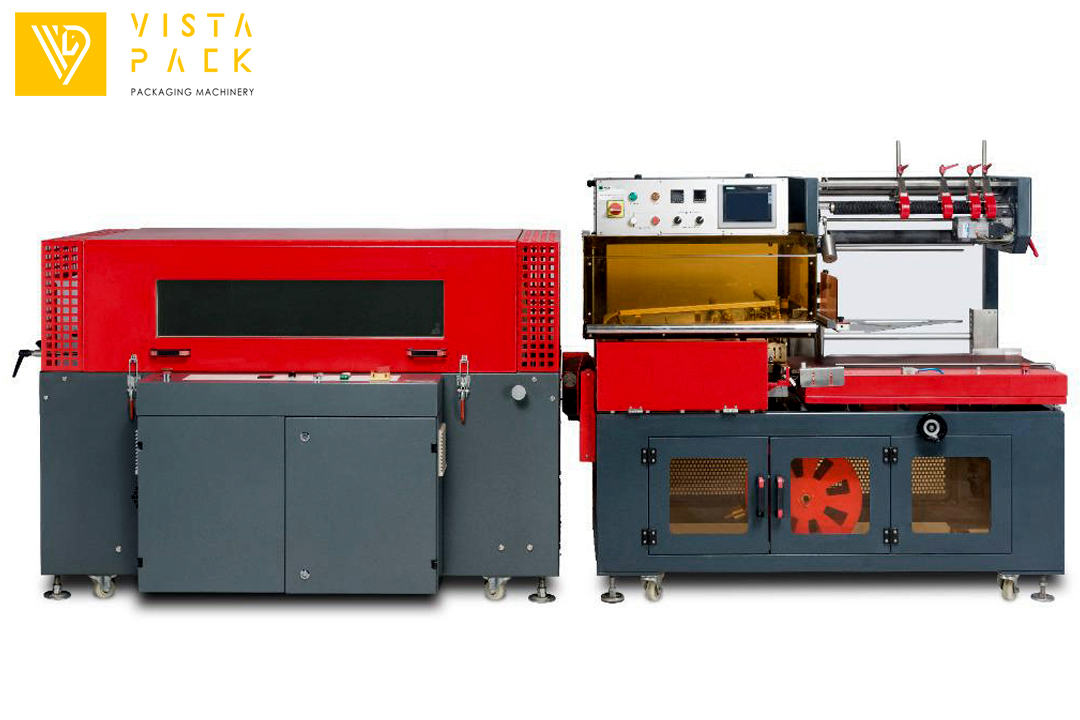

Revolutionary electric strapping machine in industrial packing Are you looking for a safe and efficient way to package your products? Vista Pack semi-automatic electric strapping machine, with a new design and advanced technology, is a response to the needs of…

Automatic strapping machine is the key to success in modern packaging Automatic side seal or gate strapping machine is a smart choice for fast, safe and efficient packing and strapping. With its unique features, this device helps improve the performance…

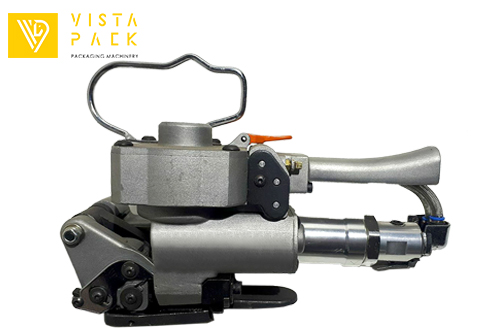

pneumatic strapping machine is an efficient solution for industrial packing In today’s world, packing plays a vital role in protecting and transporting products. Products in small to very large dimensions need to be packaged for ease of transportation. Have you…

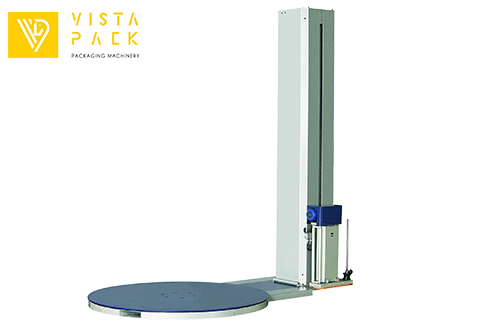

Vistapack packaging machines