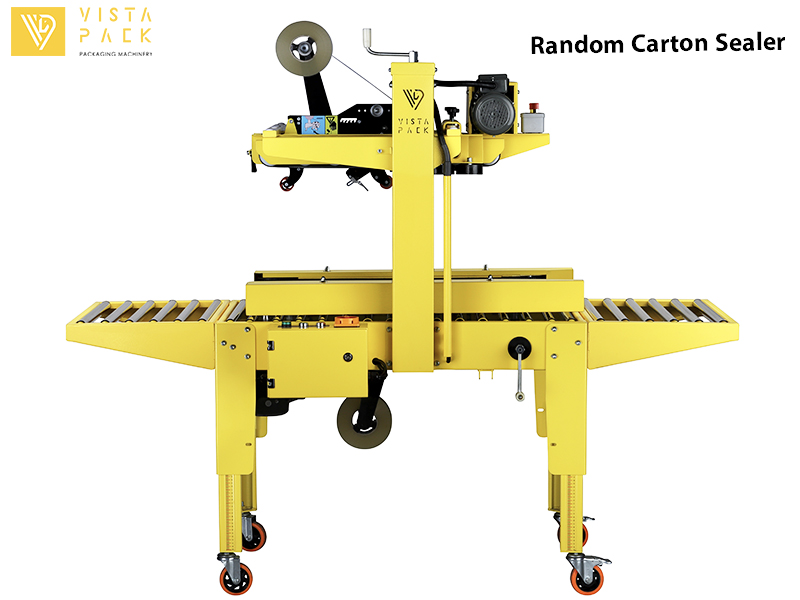

Optimizing the packaging process with an electric sealer

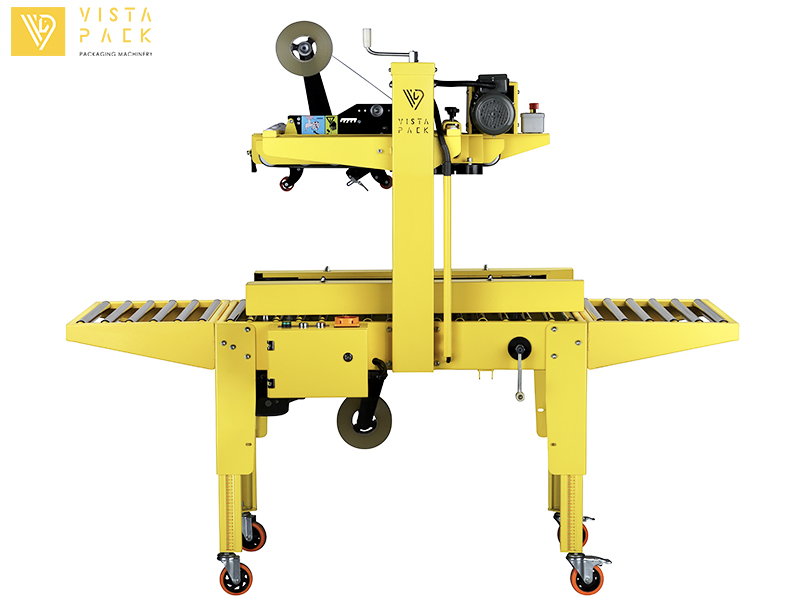

In today’s industrial world, efficiency and speed in product packaging are particularly important. One of the key equipment that can help improve the performance of factories is the self-adjusting or random electric glue machine. These devices, with their diverse capabilities, allow the packaging process to be done faster and with better quality.

Lack of manpower is one of the most important challenges in many factories. Therefore, using devices that require less manpower can help improve efficiency and reduce costs.

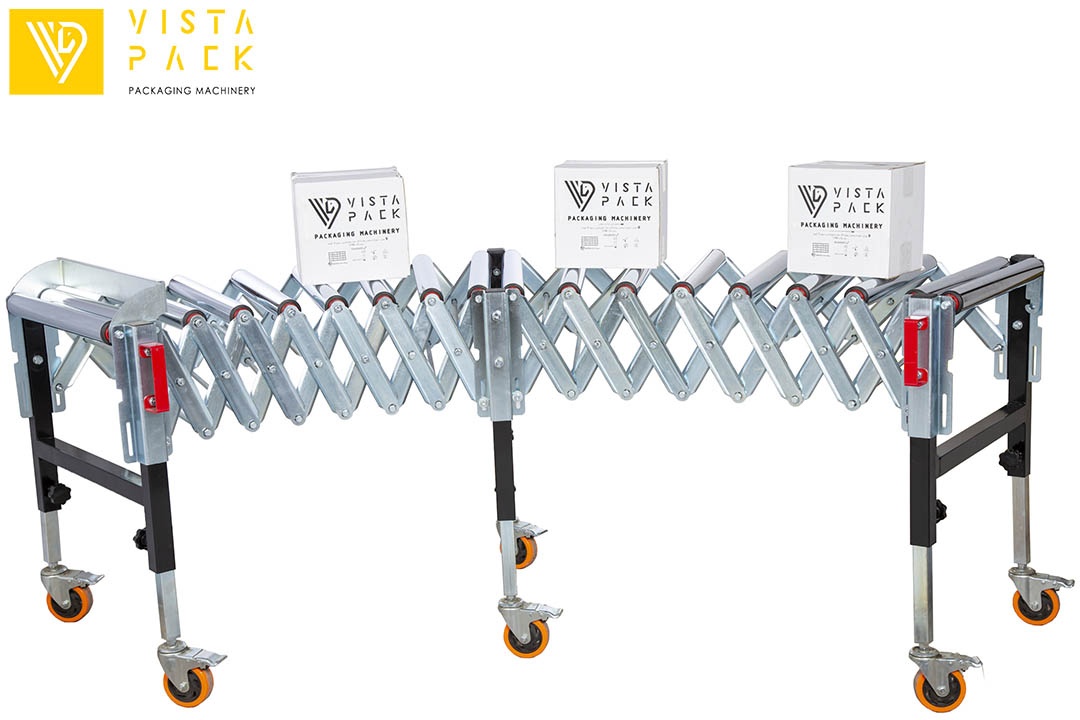

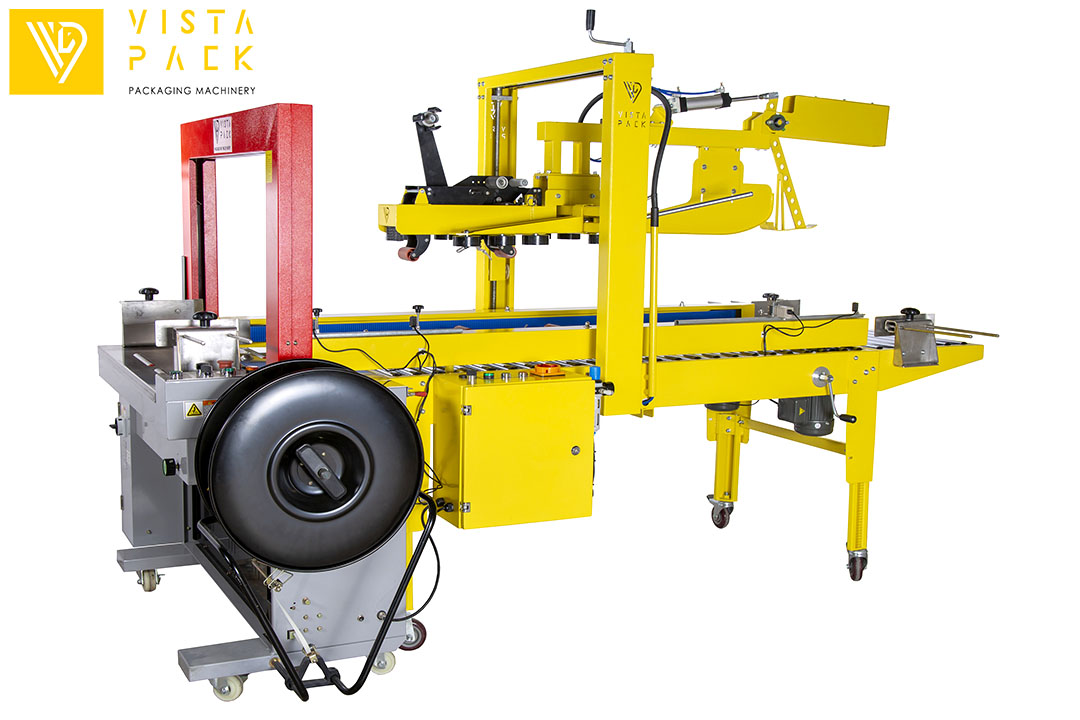

Usually, the output of several packaging lines that produce cartons of different sizes is directed to a conveyor belt. Instead of employing several machines and operators for sealer, one operator is enough to facilitate the packaging process by monitoring the operation of the electric sealer.

Carton sealer 🚀 A solution to reduce packaging costs and time

The importance of using an electric sealer

1️⃣Increase production speed

2️⃣Saving manpower

3️⃣Optimal use of raw materials

4️⃣High packing quality, uniform and resistant sealer

5️⃣No damage to packages during transportation

Ready to take your packaging to the next level? Contact us to provide new solutions for packaging your products.

Electric sealer, a smart solution for modern packaging

Are you looking for a way to increase efficiency in your packaging line? Electric sealer can be the right answer for your needs.

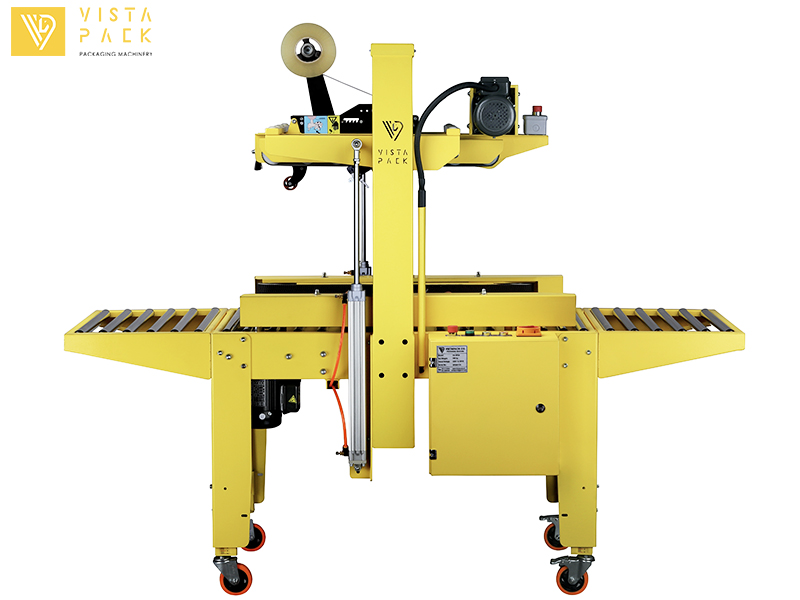

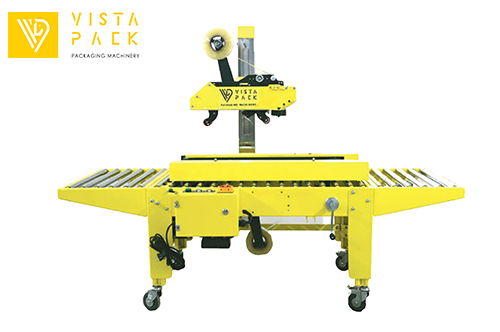

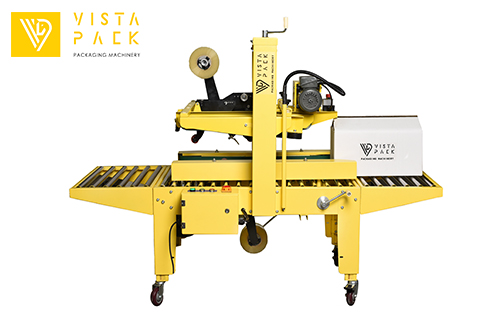

The self-adjusting carton sealer is suitable for industries where cartons of various sizes enter the packaging process. The intelligent system of this device automatically detects the dimensions of each carton and applies the necessary settings.

As a modern and efficient solution in the packaging industry, the electric gluer helps to reduce costs and increase production speed.

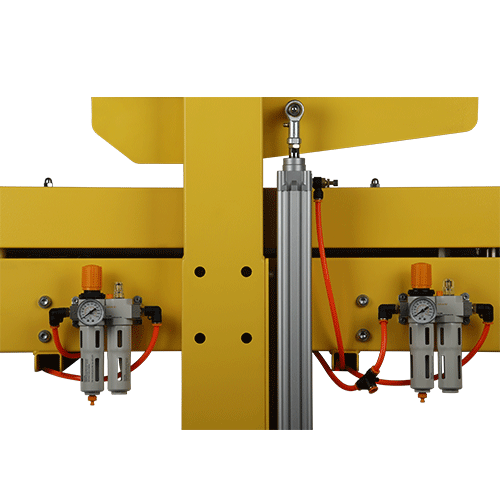

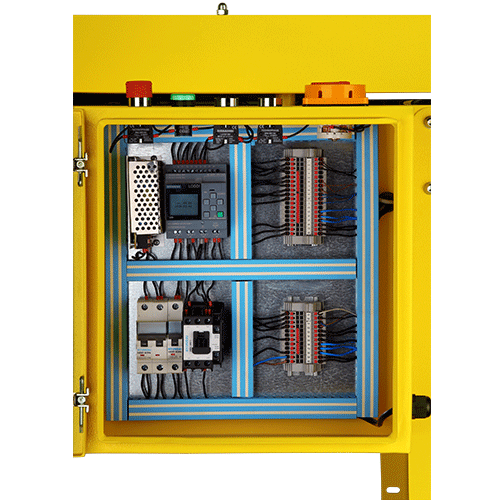

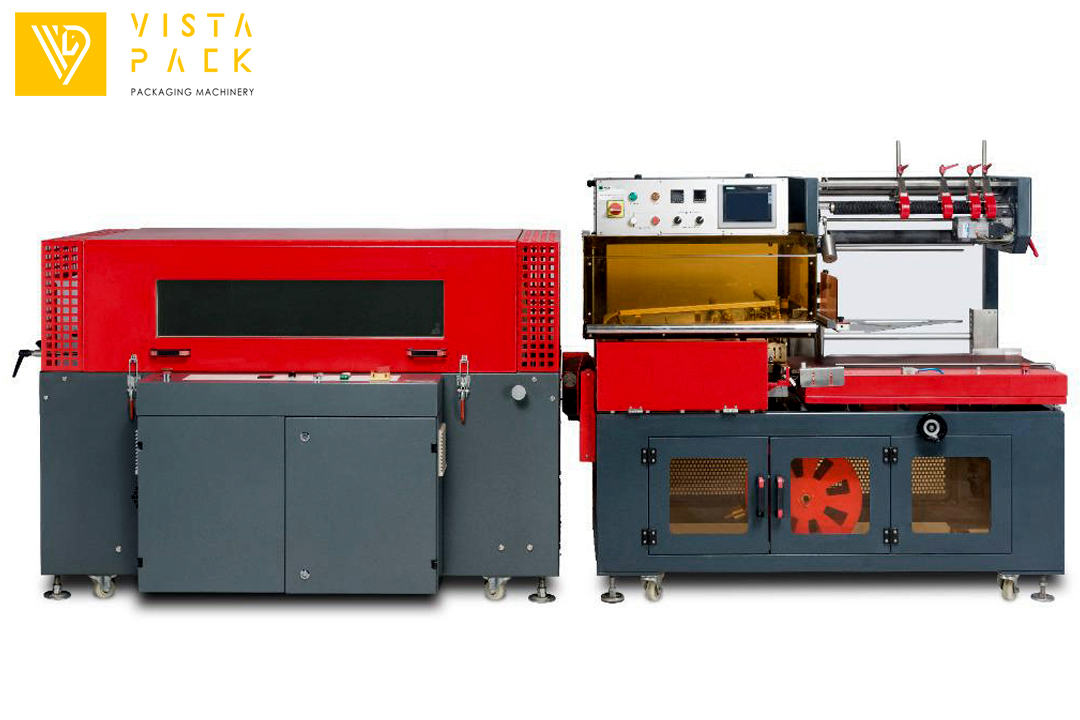

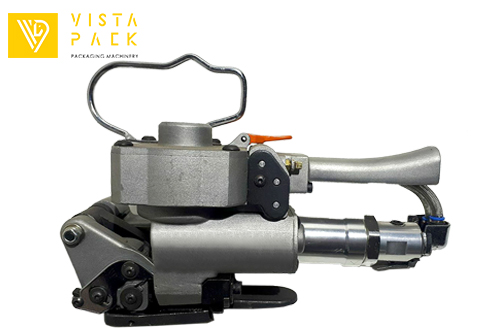

Electric sealer operate using pneumatic or air technologies and are equipped with advanced PLC control systems.

Device warranty and guarantee

- Carrying out all manual welding by certified welders

- All cuts and holes are made by laser with 02mm accuracy

- Bending of sheets with CNC Press Brake machine with very high precision

- 12 months engine and gearbox warranty

- 12-month warranty for consumable parts, including tension belts, cutting blades, and full and empty rollers

- 10 years of after-sales service

Guide to choosing a carton sealer

Pay attention to the following points in order to choose and buy a sealer correctly:

- Free consultation of Vista Pack: Get to know your needs with the help of free consultation of Vista Pack.

- Production capacity: By checking different models, choose a machine that is compatible with your production volume.

- Customer Reviews: Reading other people’s reviews can help you make a smart choice.

- Warranty and after-sales service: Make sure that the device you choose comes with a proper warranty and after-sales service.

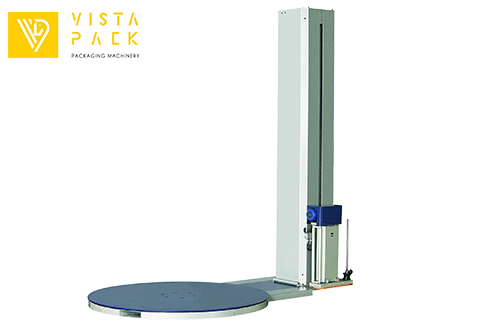

Advantages of self-adjusting carton sealer | Carry from the side

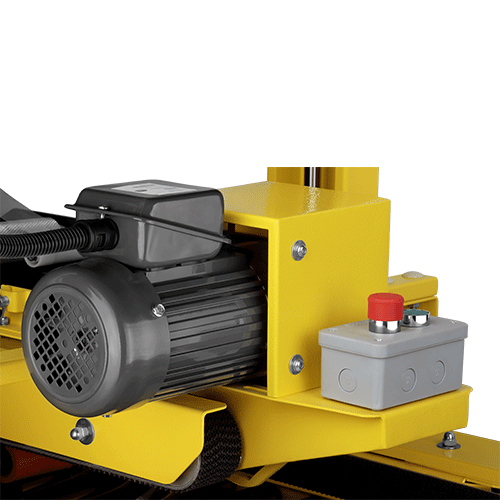

- Equipped with three powerful 200 watt single phase motors

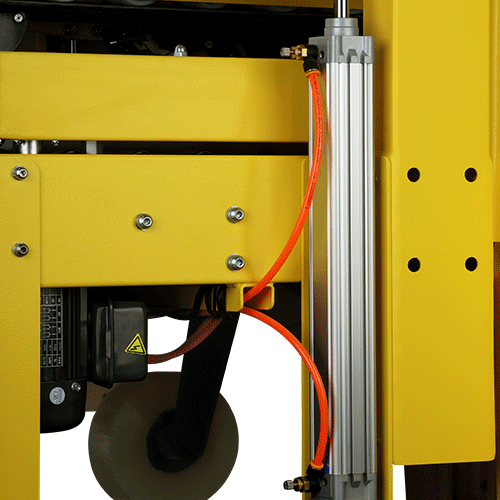

- Equipped with pneumatic jack

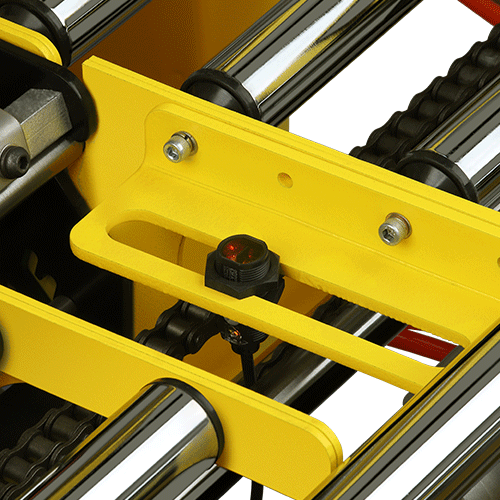

- Equipped with high quality capacitive sensor

- Equipped with two very high quality portable heads

- Equipped with high quality braked wheels

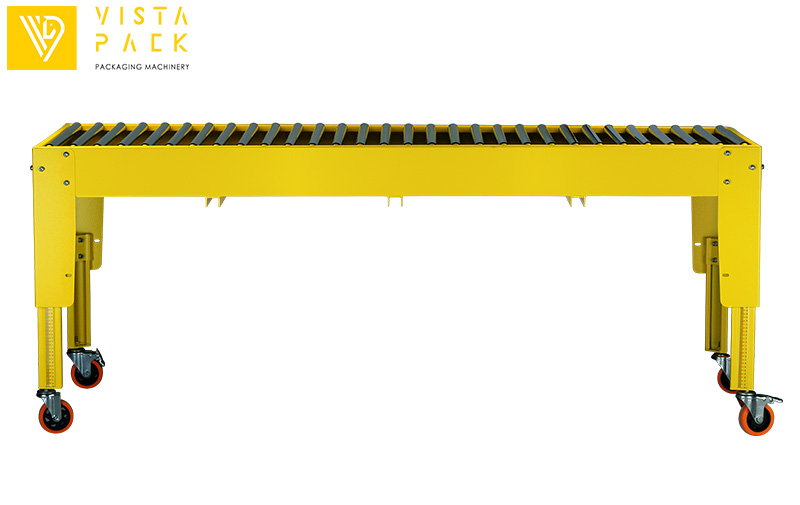

- Equipped with ball-bearing rollers for smooth movement and longer life

- The material of all rollers is nickel chrome plating or 304 steel

- Equipped with a special place for transporting by forklift

- Aluminum engine head money making

- Installation of adjustment for device cartridge springs

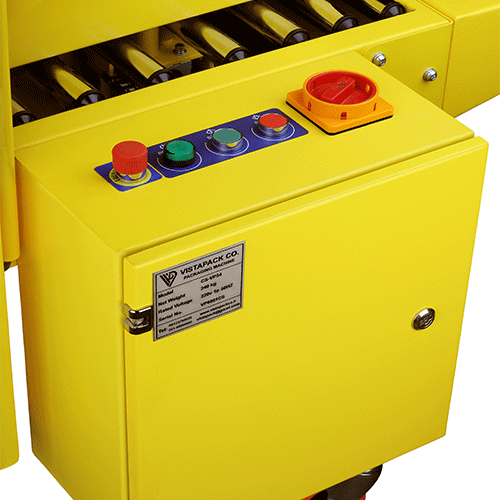

- It has an electrical panel equipped with Amren or Siemens plc and an emergency cut-off switch

- The use of protective electrical devices in the electrical panel to protect the motors and the operator

- 30% of machine cartridge parts and all machine head screws are made of 304L stainless steel

- It is equipped with a portable cartridge with two anti-wear silicone rollers (red color) with a long service life

- Making the device using high thickness sheet and double sheets technique

Technical specifications of the self-adjusting sealer | |

| Country of manufacture: Iran | Input power: single phase – 220v |

| Machine Dimensions: L:1980 mm W:995 mm H: 1525 mm | Minimum carton dimensions: W: 160mm H: 160 L:150 Maximum carton dimensions: W: 500mm H: 500mm |

| The maximum weight that can be tolerated on the roller tables at the beginning and end of the device: 100 Kg | Ability to stick glue from 40mm to 80mm wide |

| Maximum speed of the machine: 15 cartons per minute | Device height adjustment range: 650mm ~ 850mm |

| .Country of manufacture of the engine: China – First class | Machine weight: 240 kg |

| Control system of the electrical panel of the device: Stop & Start | Engine power: 3 * 200w |

| Material of head rollers: anti-wear silicone (red color) with long life | Shaft material of rollers and machine motors: nickel chrome plating |

| Brand of contactor and miniature fuse of electrical panel: Hyundai Korea. Color type of | .device: Electrostatic with color test certificate |

Comparison of semi-automatic sealer and electric sealer

Choosing between these two types of devices depends on your production needs, your workload and your budget. Semi-automatic and self-adjusting gluing machines have differences in terms of performance and features, which are mentioned below:

1️⃣Semi-automatic carton sealer

- Manual settings: Carton dimensions are set manually, which requires some time.

Suitable for small productions: these devices are suitable for small workshops or low-volume productions.

Initial cost: The initial cost of this device is less and more affordable.

2️⃣Electric sealer

Automatic function: using advanced technologies, these devices are able to detect the dimensions of the carton and automatically adjust the device accordingly. This technology leads to increased production speed and reduced human error.

Suitable for large productions: This type of device is suitable for larger factories and manufacturers.

Initial cost: The initial cost of the self-adjusting device is higher than that of the semi-automatic device.

Why is an electric sealer a better choice?

The electric glue machine has special features that distinguish it from other types of machines. In the following, I will mention the most important features of these devices:

Compatibility with all types of cartons: This machine is able to work with different types of cartons in terms of size and height.

Automatic adjustment of dimensions: Self-adjustment devices are able to identify different dimensions of cartons and automatically make the necessary adjustments. This feature saves time and increases accuracy.

Reduction of human error: By eliminating manual adjustment steps, the possibility of human error is reduced.

Cost savings: By increasing speed and efficiency, labor and raw material costs are reduced.

Ease of use: This device has a simple user interface that makes it easy for the operator to work with them.

Free consultation at 00989123798626📞To choose the gluing machine that suits your needs

Key points in maintenance and repair of carton sealer

Correct maintenance of the device not only increases its useful life, but also helps to maintain the quality and efficiency of the packaging. By observing the following tips, you can make the most of your device:

1️⃣Checking the parts: Regularly check the consumable parts of the machine, such as tension belts, cutting blades, and full and empty rollers. If any damage or wear is observed, repair or replace the damaged parts.

2️⃣Cleaning the device: Use mild detergent and soft cloths to clean the device and remove dust.

3️⃣Checking the settings: Before starting work, make sure that the settings of the machine (such as the width and height of the carton) are done correctly.

4️⃣Suitable glue: Use glue with good adhesion and high quality.

5️⃣آProper personnel training: Teach your personnel how to use the device correctly and solve possible problems.

6️⃣Maintenance of the working environment: Keep the device in a clean and dry environment and avoid exposing it to moisture and inappropriate temperatures.

7️⃣Use of original spare parts: If you need to replace spare parts, get original parts from Vistapack to maintain the device’s performance.

Sending consumable spare parts

In case of customer’s request, Spar parts used for the device, including two parts, mechanical parts and electrical parts, will be sent along with the device. Having these parts at your disposal prevents wasting capital and time when necessary.

Packing and sending the device

The Vista Pack glue machine is covered by protective nylon and packaged to prevent damage to the machine during storage and transportation. (If the customer wishes, it is also possible to send the device inside the pallet).

Transformation and innovation in the packaging industry

The electric gluer is a smart investment for factories looking to: reduce costs, increase production speed and improve packaging quality. This modern technology can revolutionize your packaging process.

Contact and more information to buy an electric sealer

Contact number 09123798626

Comments and suggestions

Dear user🖌 Help us provide better services by recording your comments and suggestions regarding packaging machines.

Reviews

There are no reviews yet.