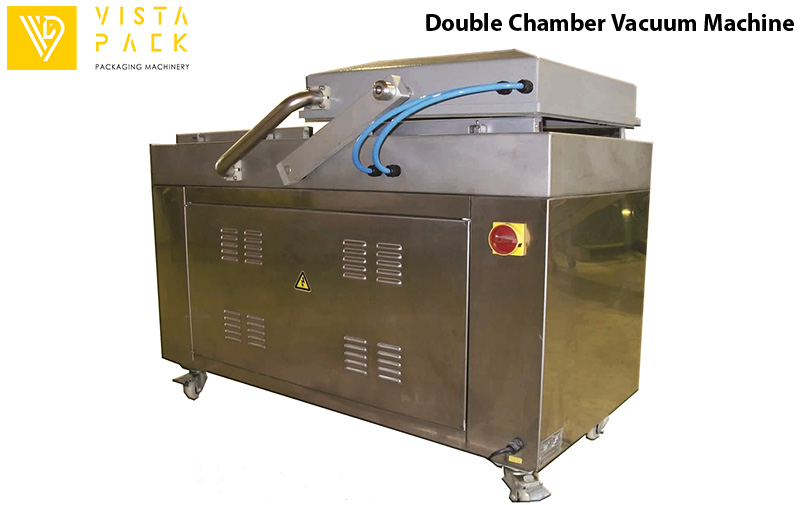

Vista Pack industrial vacuum packaging machine with a modern and user-friendly design is one of the most advanced methods of food preservation. This machine increases the shelf life of food by up to 5 times by removing air inside the package. The two-cabin machine has a high production capacity (usually 2 to 3 times that of single-cabin models), which facilitates packaging operations. The method of working with the machine is very simple, and the operator will be familiar with the operation of the machine after one training.

Vista Pack two-cabin vacuum packaging machine has the ability to inject very high quality gas upon customer request. By injecting nitrogen and nitrogen gases, the machine increases the shelf life of products and delays the onset of bacterial growth. When injecting gas, be sure to pay attention to the purity of the injected gases because they play an important role in product quality.

Free consultation with the number 00989123798626📞To choose and buy an industrial vacuum machine to your needs

💡 How it works

Product Put: The product is placed in a vacuum bag.

Closing the door: The cabin door was closed by the operator.

Air Discharge: The pump removes the air inside the package.

Heat Sewing: The edges of the sac are sewn with heat.

Door Opening: After completing the vacuum process, the device door will automatically open.

Final packing: The product is ready to maintain or distribute.

♨️ Applications

- Food maintenance in restaurants, hotels and industrial kitchens

- Packing of agricultural products

- Packing foods such as dairy products, raw meat and protein products, vegetables and fruits, beans and nuts, ready -made foods and …

- Maintenance

- Packing of industrial parts and supplies

📈Advantages

1️⃣ Made of first-class steel

2️⃣ Equipped with a transparent glass door for easy observation of the vacuum process

3️⃣ Gas injection capability to increase the shelf life of sensitive products (custom)

4️⃣ Equipped with a fully isolated element heating system

5️⃣ Using resistant coatings in the device and not affecting the taste and quality of the ingredients

6️⃣ Equipped with two powerful motors and 10 application programs for better performance

7️⃣ Equipped with 2 sewing blades in each cabin to increase packaging speed

8️⃣ High capacity of the optimal suction pump in completely emptying the air inside the packages

9️⃣ Adjusting the vacuum time based on the product’s needs

🔟 Continuous and uninterrupted operation of the device

📐 Technical specifications of the device | |

| Cabin Dimensions: 1 * 2 * Height 2 cm | Dimensions of the device: 1 * length 1 * Height 2 cm |

| Dual -enclosed | Weight of the machine: 1 kg |

| Device Voltage: Three Pils 1 W | Cutting blade length: 1 cm |

| Consumption of the device: 3 phases and V 380 and HZ 50 | A suction pump capacity: 2 cubic meters per hour |

| Maximum product height: 1 mm of suction pump 2 m | Vacuum Time: between 1 and 2 seconds depending on the amount of air discharge |

| CE Europe CE Certificate | Equipped with digital controller |

📊 Important tips for using the device

Choosing the right bag

- Vacuum bag

- Attention to appropriate size and thickness

- The examination of the heat resistance of the sac

The correct maintenance

- Maintenance at appropriate temperature

- Protects the impact and pressure

- Regular Package Health Control

Frequently Asked Questions

The three main types of industrial vacuum devices are:

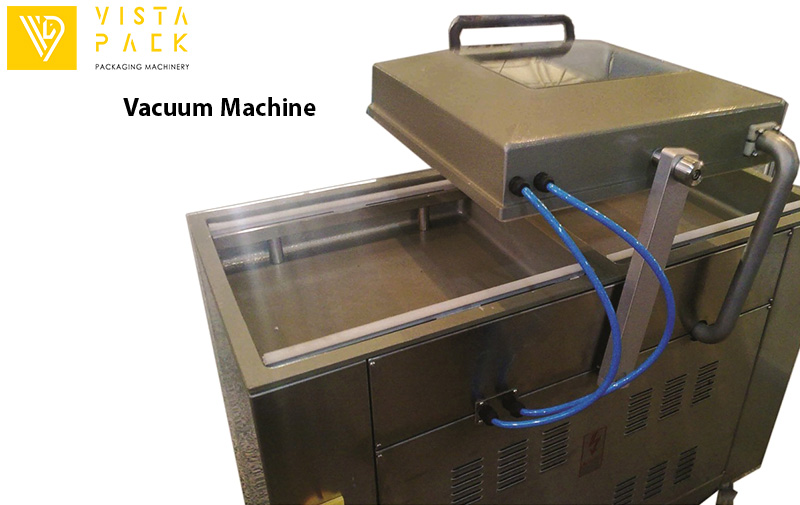

– Desktop vacuum device: suitable for home use and small businesses

– Single cabin vacuum machine: suitable for medium-sized workshops and large restaurants

– Two-cabin vacuum device: suitable for industrial production lines and large factories

The price of the device depends on various factors, including the type of application, working capacity, facilities and exchange rate fluctuations. To know the exact price, you can call 09123798626.

Yes, but certain points must be observed. For juicy items such as fresh meat or juicy fruits, the place of plastic stitching should be dry.

No, regular bags are not recommended because:

– They do not have enough resistance to vacuum pressure

– The possibility of tearing and leaking is high

– Failure to keep the freshness of the product due to the entry of oxygen

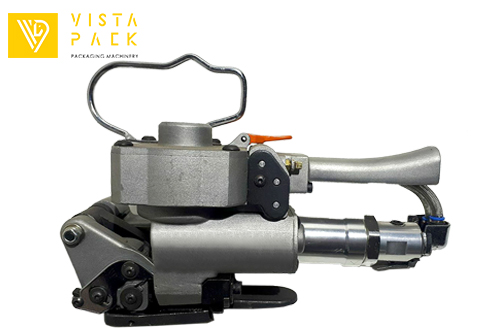

The most common consumable parts include:

– Vacuum pump oil (requires periodic replacement)

– Thermal sewing tape

– Sealing tires

– Element

– Tube

It is recommended to always have these parts available.

The industrial vacuum device is a specialized packing tool that prevents the penetration of oxygen and moisture by removing the air inside the package and thermal stitching. This process increases the shelf life of products up to 5 times.

Power consumption varies depending on the model:

– Desktop model: 300-700 W, 220 V household electricity

– Single cabin: about 1 kW, single-phase electricity 220 volts

– Two cabins: about 380 watts, requiring three-phase industrial electricity

Purchase of Vista Pack vacuum machine Packing 💪 With one -year warranty + Send all over the country

💰 What should we pay attention to when buying a device?

- Production capacity

- Product dimensions

- Vacuum pump power

- Sewing quality

- Extra capabilities

🛠Vista Pack after -sales support and service

- One -year warranty of parts and performance

- 4 -year -old after -sales service

- Technical Support and Rapid Provision of Spare Parts

Call and More Info to Purchase Vacuum Packaging

Contact Number 📞 00989123798626

Comments and suggestions

Dear user🖌 Help us better with your comments and suggestions on Vista Pack packing machines.

Reviews

There are no reviews yet.