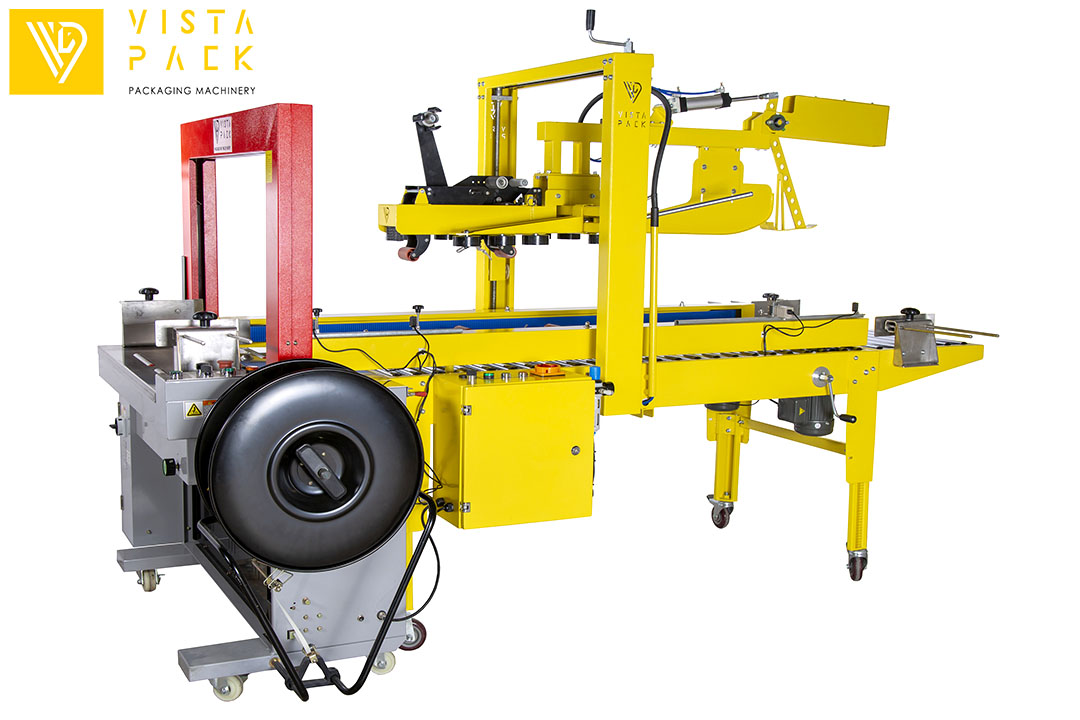

Automatic shrink wrapper machine is a modern solution for professional packaging

Packaging is the process that preserves the goods in transit to the market. Thermal shrinking is a type of transportation and final packaging of products. The thermal shrinking device packs the products in an orderly and safe manner using thermal plastic film. Shiring is the safe protection of your products to the farthest export markets on the other side of the world.

By choosing and buying the right sharing machine, the quality of product packaging will increase, operational costs will decrease, and your brand image will be improved. By providing professional and attractive packaging, this device can help increase your sales and customer satisfaction to be the leader in today’s competitive market.

What is shiring?

Sheering means putting thin nylon on the products to preserve the appearance of the packaging, prevent damage and create a beautiful appearance for the consumer.

Automatic shrink wrapper machine 🚀 Cheap and efficient solution for professional packaging

Advantages of Automatic shrink wrapper machine

1️⃣Product protection against pollution, dust, moisture and physical damage

2️⃣Improving the appearance and display of the product

3️⃣Increasing shelf life and maintaining product quality

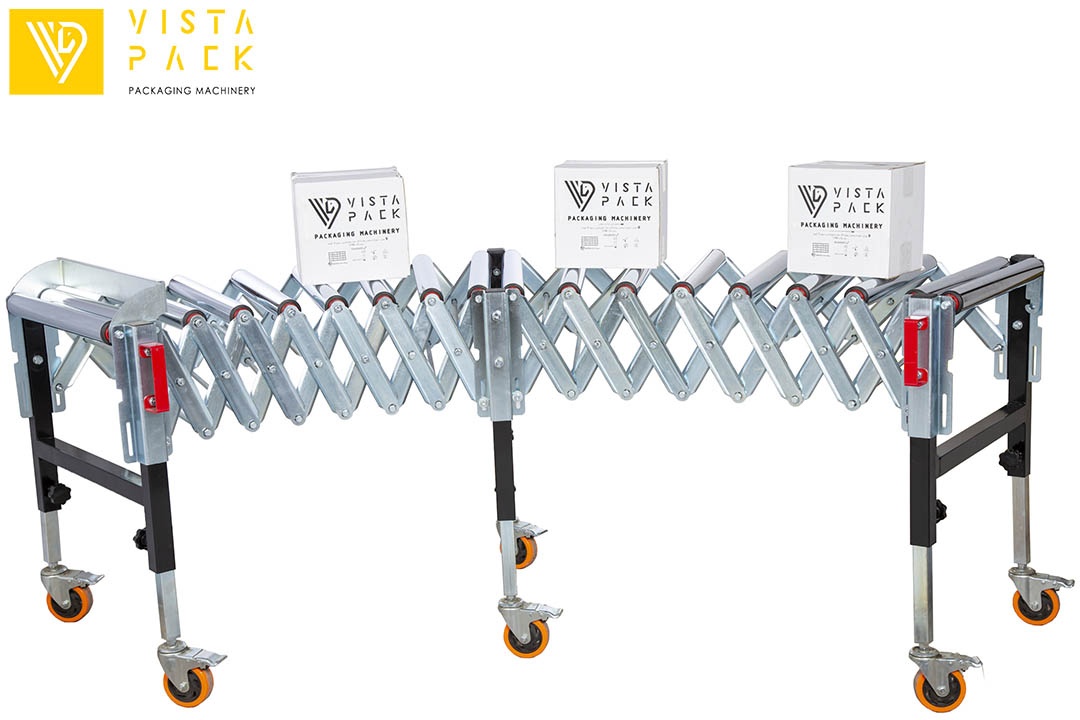

4️⃣Facilitating transportation and storage

5️⃣The possibility of grouping products (such as multiple packages of mineral water)

6️⃣Saving on packaging costs compared to traditional methods

7️⃣It is possible to print advertisements on the sheeting film

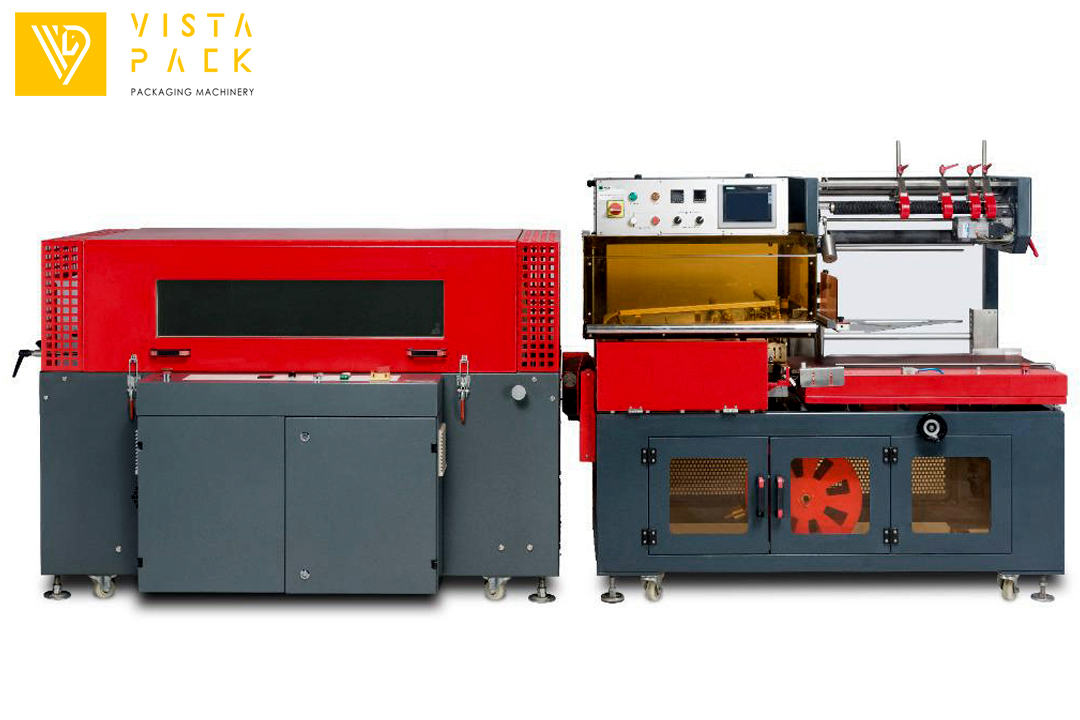

Technical specifications of shrink wrapper machine | |

| Device dimensions: 3700x980x1570 mm | Power consumption: 16 kW (three-phase electricity) |

| Maximum dimensions of the product that can be packed: 450 x 320 x 120 mm | Machine weight: 700 kg |

| Maximum speed: up to 1700 packages per hour | Ability to stick glue from 40mm to 80mm wide |

| Maximum film width: 400 mm | Minimum film width: 200 mm |

| Equipped with German Siemens touch screen | Equipped with two German Schneider Electric motor speed controls in the tunnel |

| Equipped with relay, thermo control and ssr relay with omron brand of Japan | Equipped with Taiwan Airtac brand pneumatic system |

The importance of using a Automatic shrink wrapper machine

Packaging is a vital aspect in the production and distribution process of products. We describe the importance of using a heat shrinking device below:

- Product Protection: Shring packaging protects products from physical damage, moisture, dust and contamination. This is especially important for food, pharmaceutical and electronic products.

- Maintenance and shelf life: Shiring increases the useful life of products by creating a protective layer. For perishable products, this can help reduce waste and increase profits.

- Ease of transportation and storage: Shiring packaging allows product classification. This makes it easy to move, store and transport.

- Marketing and branding: Shiring tunnel packaging allows printing product information, logos and advertisements. The transparency of the sheeting film allows the product to be seen well, which can increase its attractiveness.

- Security and authenticity of the product: Shiring packaging indicates that the product is intact. This helps prevent fraud and maintain customer trust.

- Cost optimization: Compared to some other packaging methods, shearing can be a cost-effective option. Using an automatic shearing machine can reduce labor costs.

- Regulatory Compliance: In many industries, especially in the food and pharmaceutical sectors, proper packaging is a legal requirement. Sharing can help meet these standards.

- Environmental sustainability: Shrink packaging can help reduce waste and improve efficiency in transportation, which reduces environmental impact.

Free consultation with the number 09123798626📞To choose a shiring device that suits your needs

Free consultation with the number 09123798626📞To choose a shiring device that suits your needs

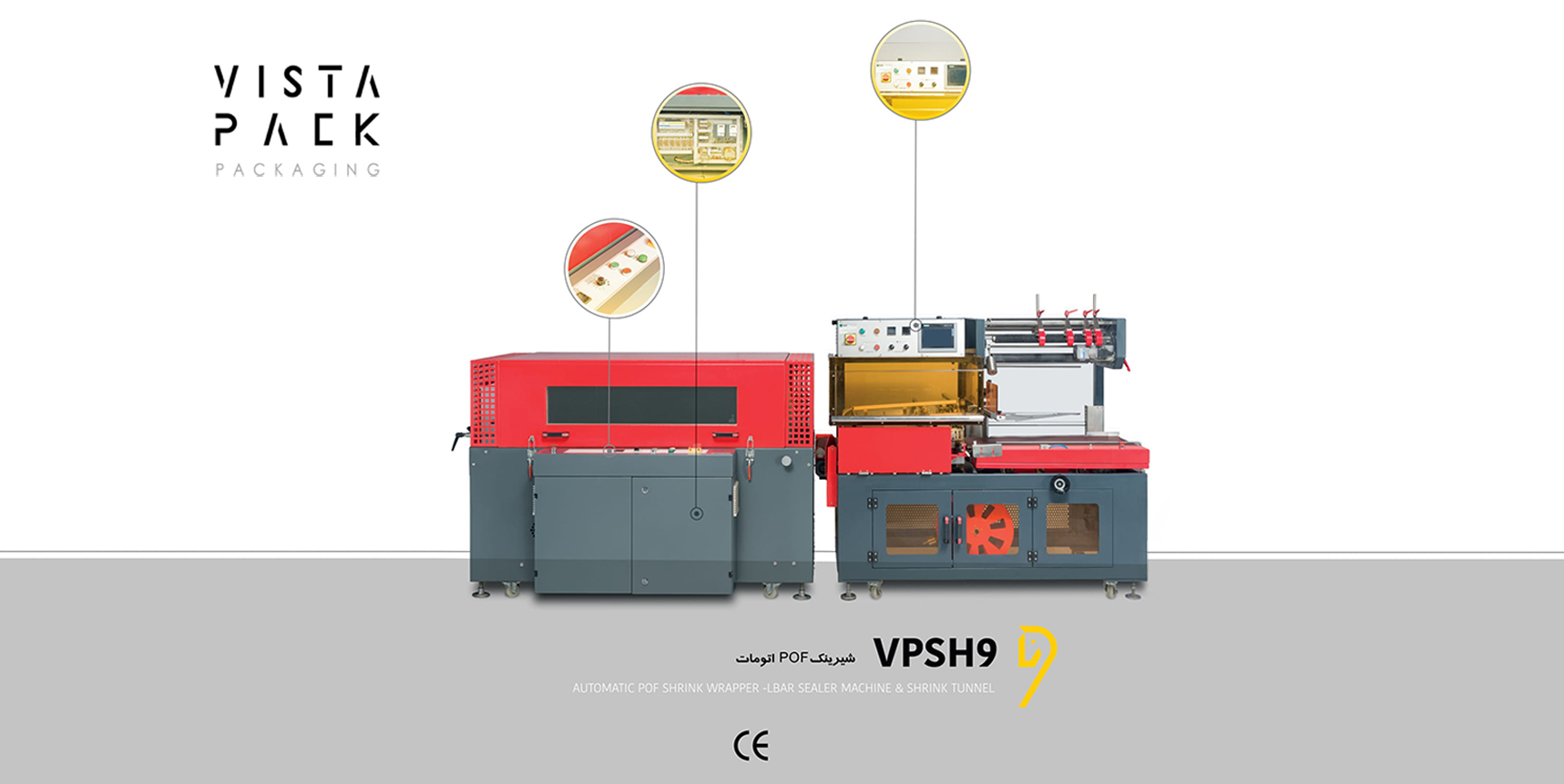

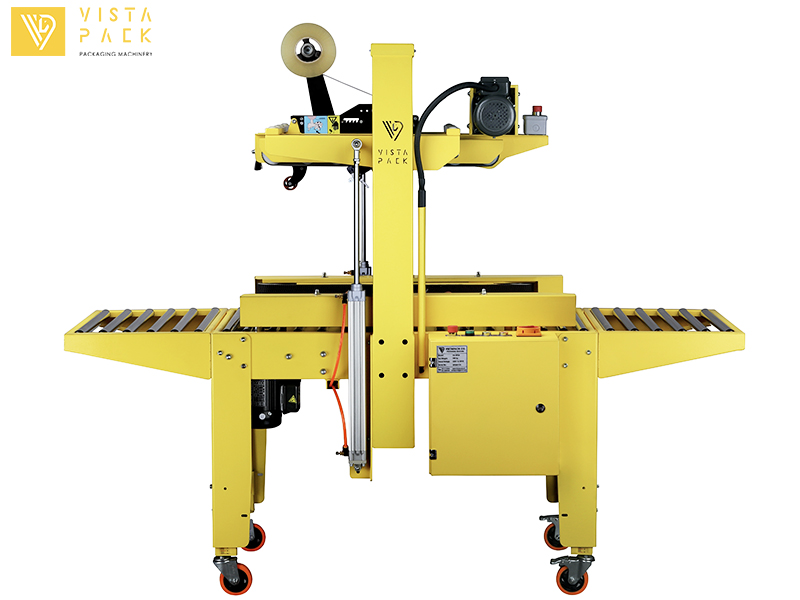

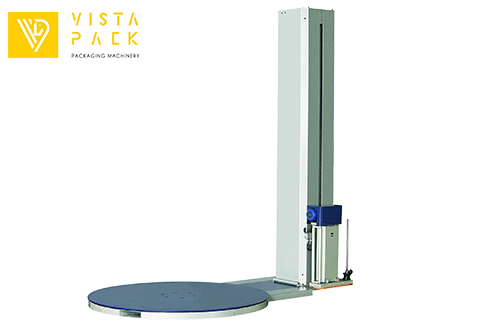

Vistapack automatic shrink wrapper machine

The tunnel shrink machine is used for packing small and large goods. The function of this system is that shrink nylon is wrapped around the product and entered into the thermal tunnel, after which the nylon is attached to the product and packs it. Shrink rolls are considered for tunnel packaging of PVC and POF polyolefin.

How the tunnel shearing machine works

For packaging, the product is first placed by the operator on the device’s input conveyor, then the product enters the thermal tunnel. Nylon is stretched around the product and is measured with the help of L-shaped stitching. Then the air inside the package is discharged and exits from the conveyor belt at the end of the tunnel. Then the cellophane product is removed by the operator.

Improving the safety and durability of products with advanced shearing technology

automatic shrink wrapper machine is an efficient tool for packaging products in various industries. This type of packaging is suitable for products whose elegance and appearance are of great value for packaging.

- Food and beverage industry

- Sanitary, cosmetic and medicinal supplies

- Industrial products

- Pharmaceutical products and medical equipment

- Household and electronic appliances

- Automotive industry

- Printing and publishing industries (book and magazine packaging)

- Catering and restaurant

Important points in choosing and buying a shearing machine

What are the important points before buying Shiring? Buying a shearing machine can significantly help improve product quality, increase efficiency in production and distribution, and ultimately increase customer satisfaction and business profitability. Guarantee the safety of your goods by purchasing the VISTA PACK sharing device.

When buying, you should pay attention to the following points:

- Product type and dimensions

- Production volume and required speed

- Available workshop or factory space

- Budget and operating expenses

Contact and more information to buy a shiring machine

Contact number 09123798626

Comments and suggestions

dear user🖌 By registering your comments and suggestions regarding VISTA PACK packaging machines, help us provide better services.

Reviews

There are no reviews yet.