Stretch pallet machines play an important role in maintaining quality, preventing damage and reducing costs by safely and securely packaging products. This machine uses stretch nylon to create a protective layer around the product to protect it from physical damage, moisture and dust. Stretch pallets are one of the most popular tools in the packaging industry due to their savings in packaging materials and increased productivity.

Free consultation at 00989123798626📞To Buy Stretch Wrap Machine according to your needs

Types of stretch pallet machines from turntable to airport⚙️

Vista Pack Company, using expert staff and advanced technology, offers high-quality and efficient stretch pallet machines. Vista Pack’s goal is to improve the quality of packaging and increase the productivity of various industries. In the following, we will examine the types of stretch pallet machines, their features, benefits and applications.

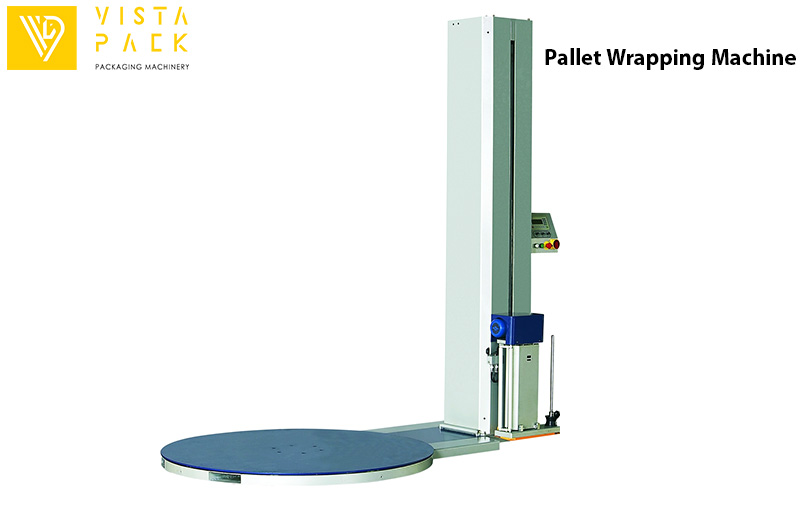

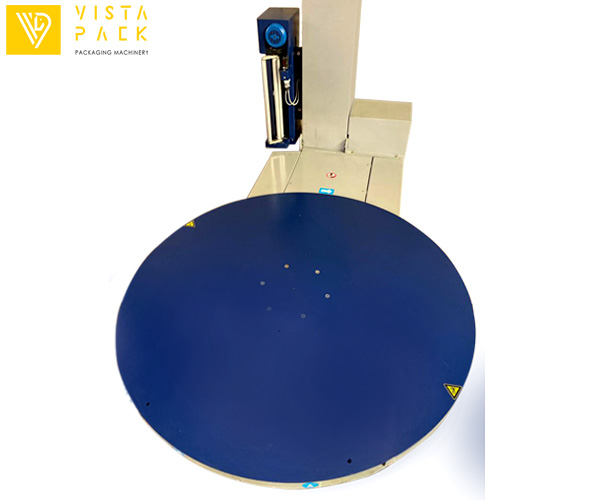

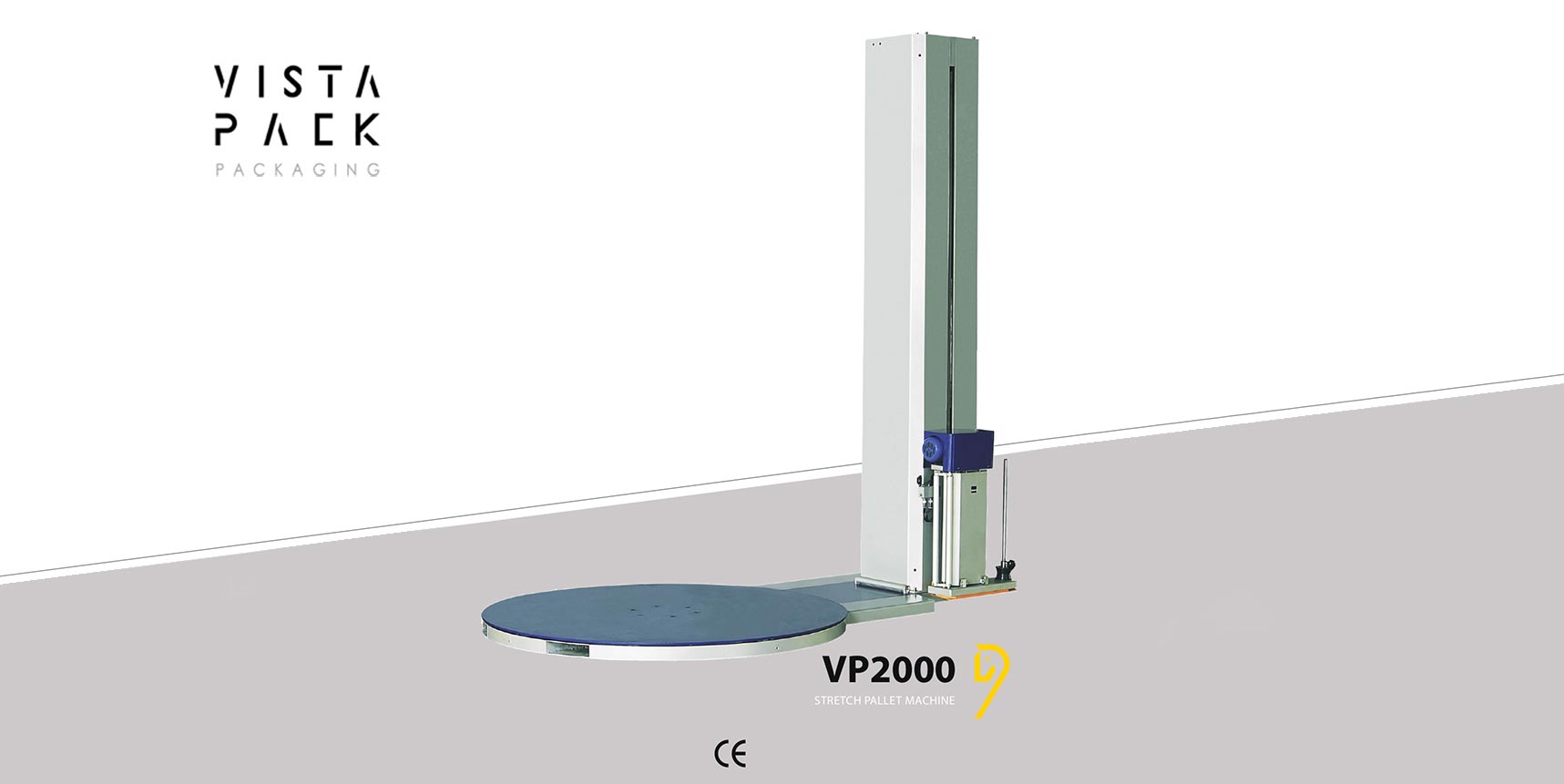

1️⃣Turntable stretch pallet

Vista Pack’s turntable stretch pallet is one of the most widely used models of stretch pallet machines, the turntable type. The turntable stretch pallet is used for packaging and wrapping pallets in various sizes and dimensions such as beverage bottles, fabric rolls, bricks, stacked cartons, etc.

2️⃣Airport stretch pallet

Vista Pack’s airport stretch pallet is used in airports and passenger terminals to pack luggage and passengers’ belongings.

The single-cabin or single-chamber vacuum machine has dimensions suitable for limited spaces and small to medium-sized workshops.

Vista Pack Stretch Pallet Machine 🚀A Smart Solution for Safe Packaging