weighing filling machine is a quick and accurate solution for filling products at the same time

weighing filling machine are one of the most important developments in packaging technology. Filling helps manufacturers to pack their products quickly, with high precision and hygienically.

Due to its special features, the weighing filling machine is of interest to many industries. Each of the device’s features are designed to increase accuracy, efficiency and useful life. These features help manufacturers to make the best use of the device.

Free consultation at 00989123798626📞To choose and buy a weighing filling machine according to your needs

The advantages of using the Vista pack multi-nozzle weighing filling machine in the production line

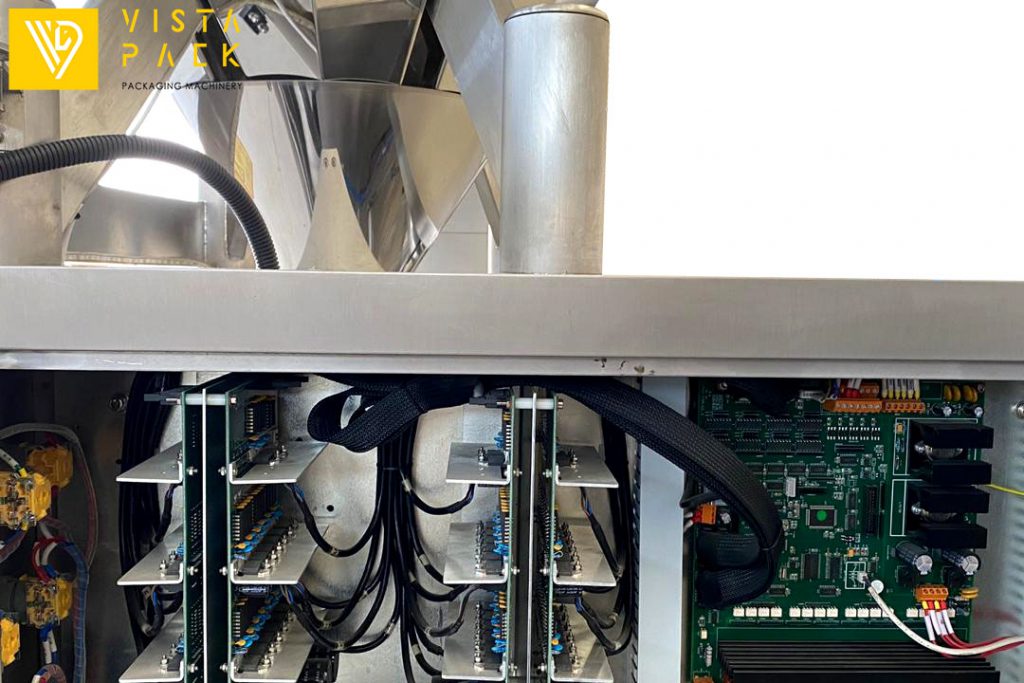

1️⃣ Touch screen and advanced software: the weighing filling machine has a touch screen with the ability to display detailed information about the device’s performance. The advanced software installed on the device reduces errors and allows different programs to be set for different products.

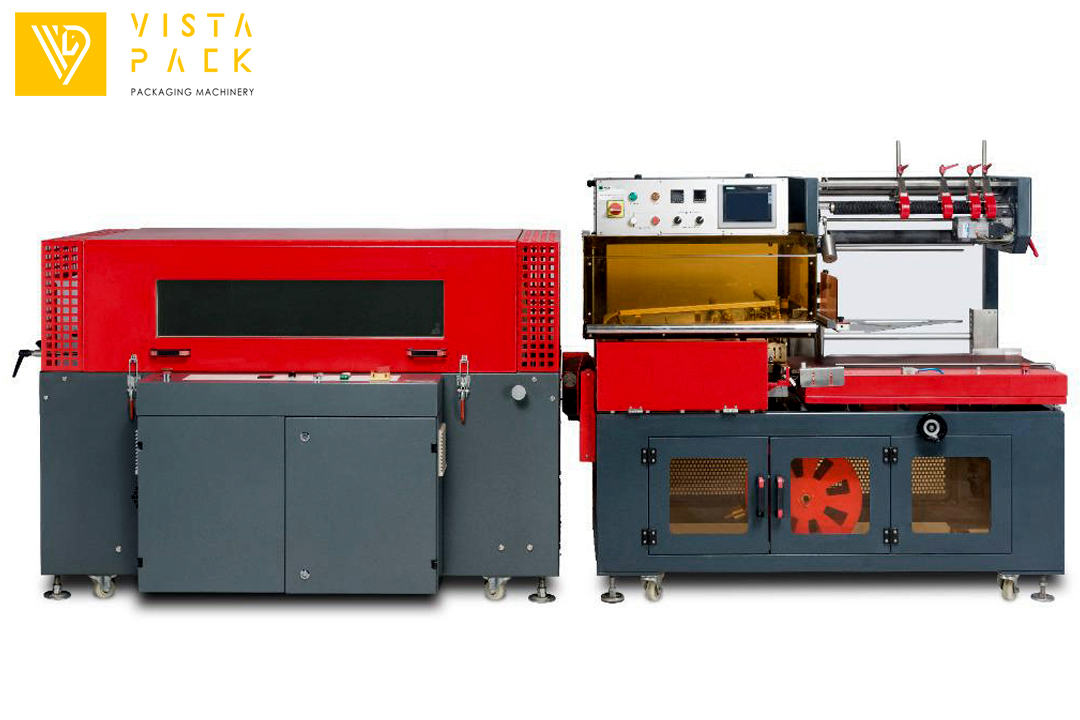

2️⃣ PID thermal control system: using the pid controller thermal control system instead of using tolerance tolerance relays, adjusts the temperature of the device continuously and accurately and prevents temperature fluctuations. Other devices that have a relay system and the temperature drops up to 10 degrees. This feature is very useful for packing materials that are sensitive to temperature changes.

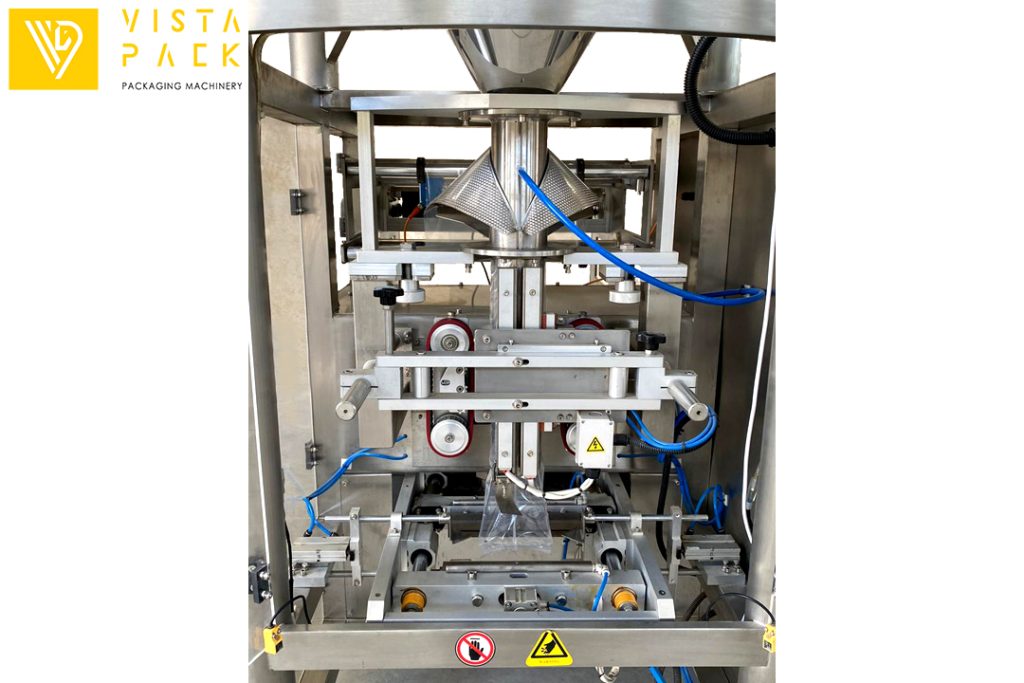

3️⃣ Maintaining the quality and hygiene of the products: due to the precise design and quality materials, the multi-head filler allows compliance with health standards. The body and filling parts of the weighing filling machine are made of quality steel, which allows washing and maintaining hygiene.

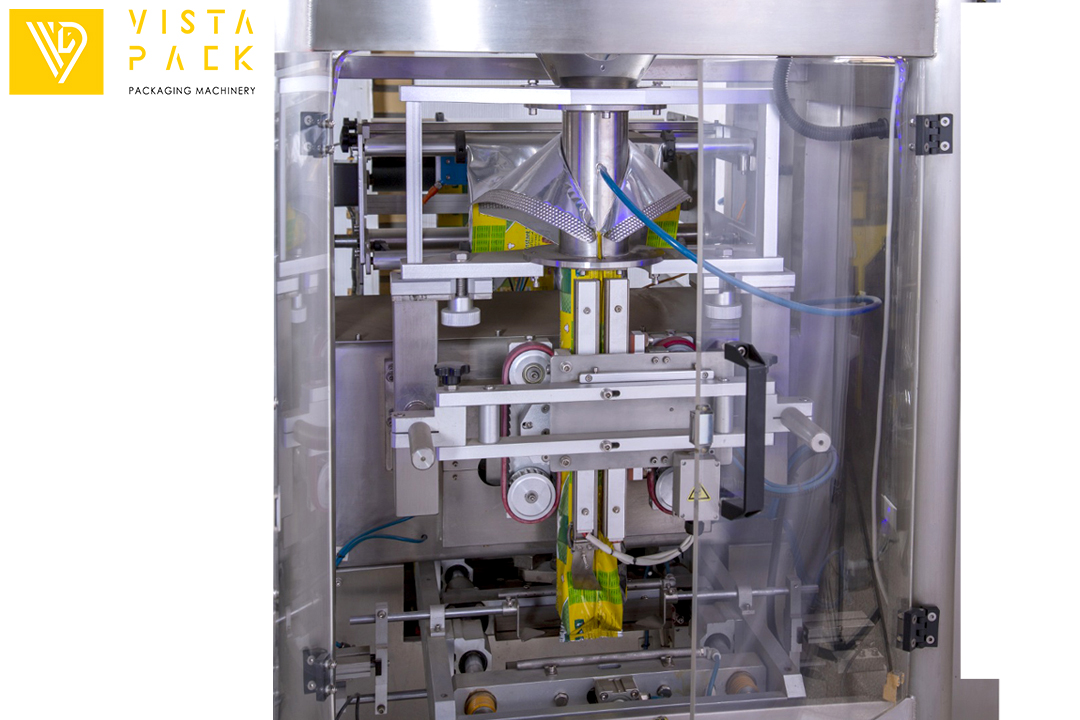

4️⃣ High speed in packing: this machine can pack products at a speed of about 80 packages per minute. High speed leads to a high volume of products being packed in a short time.

5️⃣ Maintenance: The use of high-quality materials makes the device have a long life and rarely requires maintenance. This feature reduces additional maintenance costs and avoids delays in the production line.

6️⃣ First-class parts: the filling machine is equipped with servo motor for cellophane, servo motor for horizontal jaw with Panasonic brand, eye mark sick sensor from Germany, sew motor from Germany, Schneider Electric inverter from France, Schneider inverter from Germany. Also, the driving force of the cellophane system is provided by Japan’s Panasonic servo motor.

7️⃣ Advanced systems: the device is equipped with an advanced sewing system for envelopes and non-permeability of air inside the packages. Also, a pneumatic jack has been used to increase the lifespan of the jaws.

Specifications of Vista Pack weighing filling machine | |

| Dimensions: 1.1 x 1.5 x 2.6 meters | Power consumption: single phase voltage |

| Minimum package weight: 20 grams | Maximum film width: 52 cm |

| Equipped with a thermal printer to insert the date | Maximum accuracy: 0.1 gram |

| Machine weight: 650 kg | It has a material detection sensor |

| Equipped with guest envelopes system | Equipped with the possibility of nitrogen gas injection |

| It has 99 variable programs for weighing | Counting the number of packaging pieces in each work shift |

| Polycarbonate spoons installed on the lifter | The maximum width of nylon output of the device: 25 cm with the ability to replace the collar tube |

| Power consumption: 220 volts | Multi-head weighing, Z lift and chain inside the lift made of steel |

weighing filling machine 💪A solution to maintain increased speed and accuracy in packing

Vista Pack weighing filling machine

The weighing filling machine has the ability to adjust and adapt to all types of grain and granular products. This machine is suitable for packing materials of different shapes and sizes such as dried fruits, coffee beans, beans, chocolate, biscuits, chips and even small industrial parts. This device can be used in different production lines without charge.

It is very easy to work with the machine and they work fully automatically, minimizing the need for human labor for manual packaging. By using this device, it is possible to reduce costs related to human resources and increase productivity. Also, reducing the number of employees in the packing department also leads to a reduction in errors and work injuries.

The Vista Pack filler has 12 multi-head scales to measure the weight of products with high accuracy (up to one gram). The high accuracy of weighing allows manufacturers to pack their products without any waste and maintain the quality and uniformity of each package.

How the weighing filling machine works

stage 1️⃣: Filling the primary tank

In the first step, the operator transfers the desired product to the primary tank of the device. The tank is installed on the lifter and has a vibrator that helps to adjust the intensity of the product flow.

stage 2️⃣: Accurate product weighing

The product is directed to the scales through the elevator. The weighing filling machine measures the weight of each measure with high accuracy (up to one gram) and determines the exact amount of product required for each package.

stage 3️⃣: Final packing and sewing

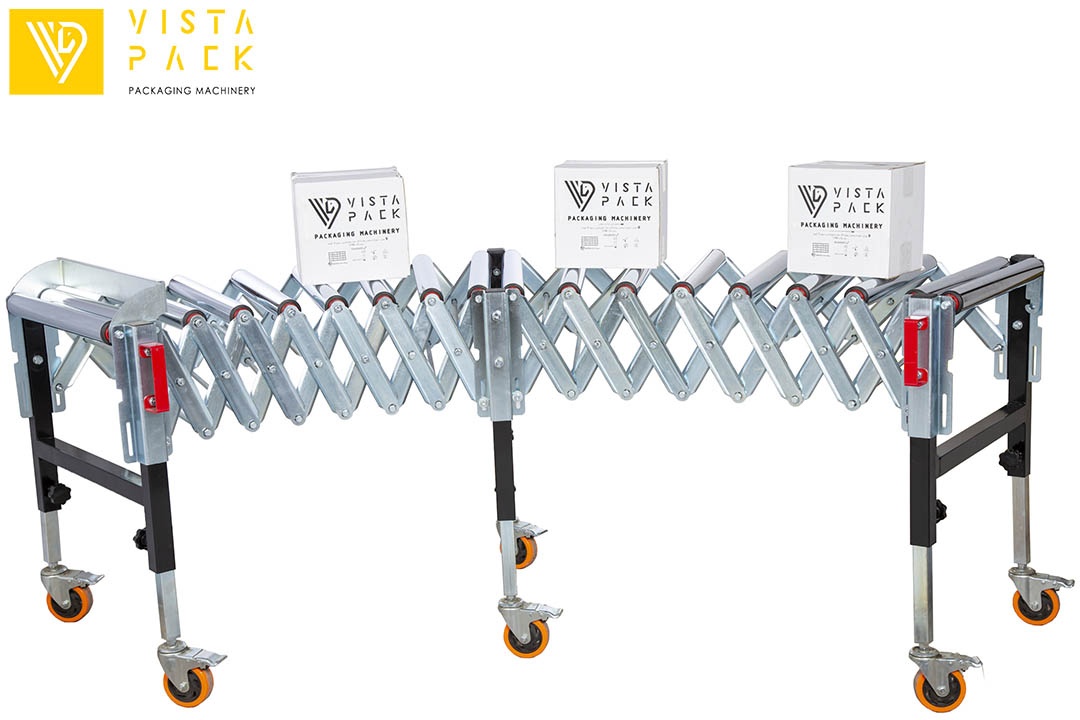

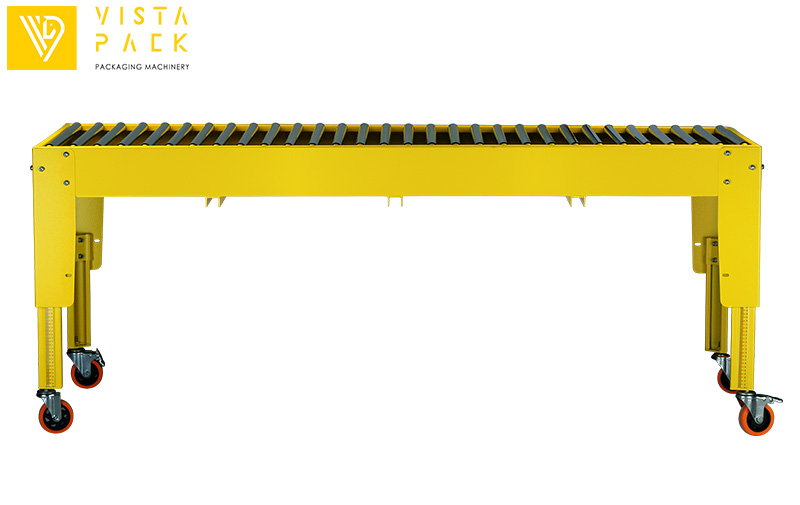

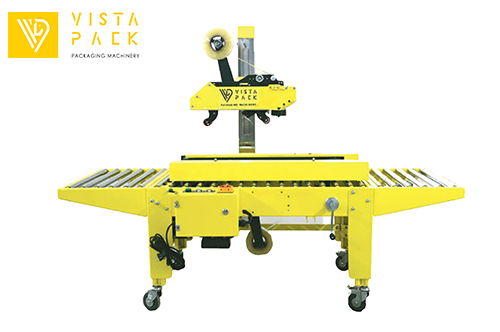

After accurate weighing, the product is poured into a special nylon that is sewn on one side. The machine automatically sews the other side of the package and the final product comes out of the machine in the form of a pillow package or an envelope.With the help of the conveyor belt, the product will be moved to the next part for packaging in cartons. Ready-to-use packages can stand upright, which is useful for stores and retailers.

Various applications of the weighing filling machine

The weighing filling machine is used in the following industries and can be used in the packing of various products.

- Food industry: This machine is widely used in the food industry and is suitable for packing materials such as nuts, chips, snacks and chocolate.

- Pharmaceutical and health industries: weighing filling machine is used for accurate packing of medicines and health products that require accurate weighing.

- Chemical and industrial industries: Multihead filler is used for packing chemical and industrial products such as small plastic and metal parts.

The weighing filling machine is designed to be fully automatic and requires human power. However, the presence of an operator is necessary to fill the tank and monitor the operation of the machine.

Yes, Vista pack Packing Industries offers one year warranty and 10 years after-sales service for theweighing filling machine, which gives manufacturers more confidence.

This device measures the weight of products up to about one gram with very high accuracy and minimum tolerance. It is even possible to set different programs for different weights.

This machine is suitable for granular and granular products such as dried fruit, chocolate, coffee, beans, tea and even industrial products such as plastic and metal parts.

Yes, the weighing filling machine is designed in such a way that in case of problems, its parts such as the cups can be easily replaced and cleaned. This feature is especially important in the parts that are in contact with the product.

Why do packing industries need a weighing filling machine?

- Increasing production speed and productivity

- Improving the quality of packing

- High precision in weighing

- Reduce packaging time

- High build quality

- Reducing manpower costs

- Reduce human errors

- Maintaining product quality and hygiene

- Ability to pack for different products

Professional multi-nozzle filling machine 💪 For packing granular products in various industries

Practical recommendations for optimal use of the weighing filling machine

Below are some practical recommendations for optimal use and increasing the useful life of the weighing filling machine:

- Regular maintenance and cleaning: due to the contact of the device with food or industrial products, regular cleaning of parts such as measures and tank is required. Using suitable detergents and following hygiene instructions will increase the life of the device.

- Precise adjustment of the thermal system: proper temperature adjustment helps to reduce problems such as nylon sticking or reducing the quality of packing.

- Periodic inspection and calibration: Periodically, inspect the device and ensure accurate operation of weighing and adjustment programs. This helps reduce errors and increase packing accuracy.

- Operator training: In order to avoid human errors and increase the productivity of the device, inform the operators of how to operate and use the device correctly.

- Using quality film rolls: using high-quality materials compatible with the device can prevent damage to the collar and nylon and provide quality and suitable packing.

Buying guide for weighing filling machine

The use of advanced and automatic devices such as the weighing filling machine can have a great impact on the profitability of your business. Buying a weighing filling machine is a valuable investment that will reduce costs and increase income in the long run. In today’s competitive market, by offering packaged products with quality and standard, attract the attention of more customers.

Buy Vista Pack packing machine 💪 With a one-year warranty + shipping nationwide

Support and after-sales service of Vista Pack

- One year parts and performance warranty

- 10-year after-sales service

- Technical support and fast supply of spare parts

Why Vista Pack?

Vista Pack Packaging Industries, with the brand VISTA PACK and 15 years of experience and the use of expert and experienced staff, is the best supplier of weighing filling machine in Iran. VISTA PACK is ready to provide services to dear customers in Iran.

To know the price of the device and get advice, you can contact our experts.

Contact and more information to buy vacuum packing

Contact number 00989123798626📞

Comments and suggestions

dear user 🖌 By registering your comments and suggestions regarding VISTA PACK packing machines, help us provide better services.

Reviews

There are no reviews yet.