pneumatic strapping machine is an efficient solution for industrial packing

In today’s world, packing plays a vital role in protecting and transporting products. Products in small to very large dimensions need to be packaged for ease of transportation.

Have you ever wondered how large and heavy packages are packed quickly and accurately in factories and warehouses? The answer to this question is a manual or pneumatic automatic strapping machine.

Manual or pneumatic strapping machine, which is sometimes called pneumatic or pneumatic strapping machine, is one of the most widely used packaging tools. Combining efficiency, ease of use and flexibility, the pneumatic strapping machine offers an ideal solution for modern industrial packaging needs.

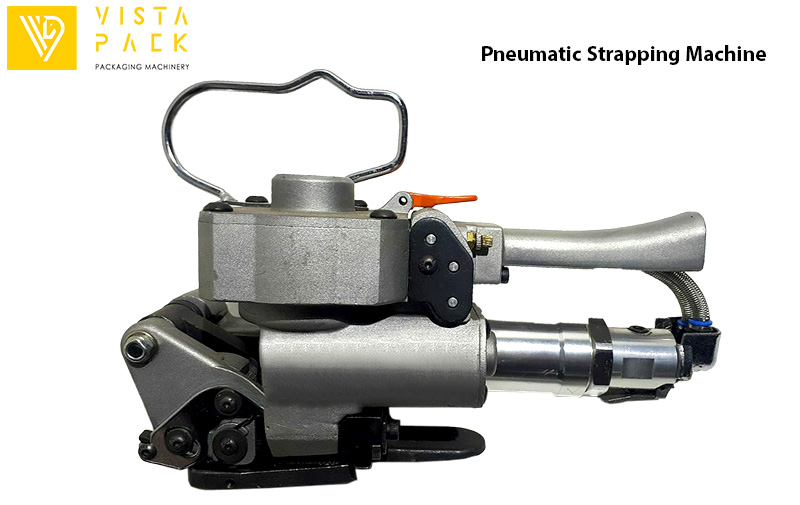

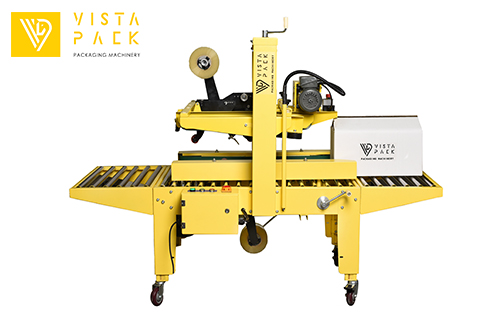

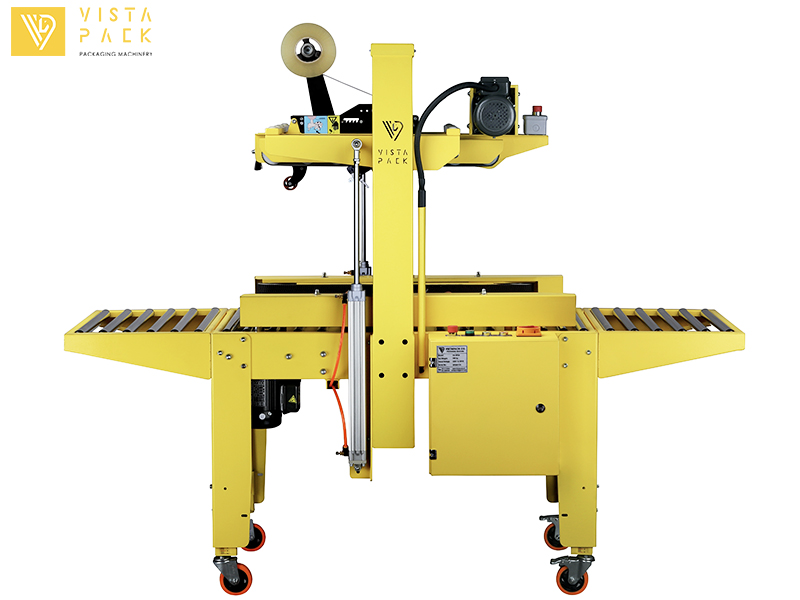

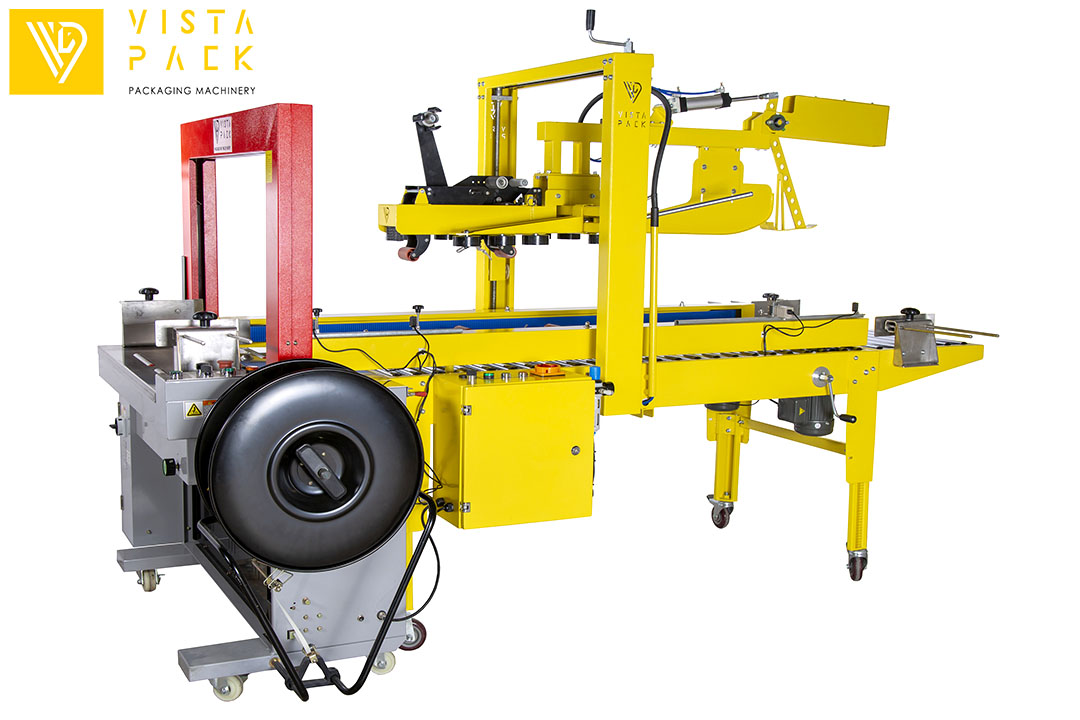

Vista pack pneumatic strapping machine

Hand strapping is used to fasten plastic straps around large packages to maintain the security and integrity of the packages. Manual tensioner (pneumatic) works by using compressed air power, that’s why it is called “pneumatic”.

Vista pack pneumatic strapping machine is a three-function device that performs all three stages of pneumatic strapping machine, pressing, friction stitching and belt cutting at the same time.

The pneumatic strapping machine is designed for large products and has high flexibility in industrial environments due to its light weight and easy portability.

Free consultation with no 00989123798626📞To choose a manual belt according to your needs

Advantages and unique features of the pneumatic strapping machine

Compared to other types of strapping, manual pneumatic strapping machine have the following significant advantages.

1️⃣ Light weight: Unlike large industrial machines, this machine is light and portable and very easy to use.

2️⃣ Wind operation: It works by using compressed wind power, which is provided by a special wind pump. Compressed air force ensures that the belt closes with power and precision.

3️⃣ High speed: it has the ability to pack the product in a few seconds.

4️⃣ Two-step process: First, he wraps the belt around the product and then performs the sewing operation.

5️⃣ Suitable for heavy products: It is ideal for packaging bulky and heavy products such as tiles and ceramics.

6️⃣ Greater safety: Reduces the risk of injuries caused by manual fastening of seat belts.

7️⃣ Cost savings: It reduces costs by increasing work speed and reducing manpower.

8️⃣ Environmentally friendly: Due to the use of wind power, it is less polluting than electric devices.

9️⃣ Flexibility: it has the ability to use all kinds of belts with different sizes.

Technical specifications of manual or pneumatic strapping machine | |

| The dimensions of the device are 130 x 115 x 275 mm | Portable and portable |

| The power of the device is 3000 newtons | The weight of the device is 3.8 kg |

| Welding resistance of PET belt up to 2 tons for each belt | Air supply or air pressure of the device 6 bar |

| Machine belt made of P.P or PET | Belt width mm (16-19) |

| Belt thickness mm (0.5-1.5) | No need for electricity or metal fasteners |

| High degree of automation | Beautiful design and high level of automation |

Vista Pack pneumatic strapping machine 🚀 Professional solution for industrial packing

Operation steps of the Pneumatic Strapping Machine

- compression stage

🔸Compressed air enters the cylinder

🔸The piston is under pressure - Connection stage

🔸The upper part of the piston is connected to the vibrating bar.

🔸The connection is made through a ring pin.

🔸An oval hole is located in the center of the vibrating bar. - Movement and vibration stage

🔸The pneumatic motor rotates at a speed of 10,000 rpm.

🔸The vibrating bar makes a quick reciprocating motion.

🔸The lower part of the belt remains fixed.

🔸The upper part of the belt is subjected to severe friction. - welding stage

🔸Friction creates heat

🔸The heat causes the belt to melt

🔸After the time set in the timer, the vibration stops and the welding is complete.

How the pneumatic strapping machine works

- Preparation: First, we put the belt around the package and put its two ends in the machine.

- Activation: by pressing the button, compressed air enters the device.

- Tension: The device pulls the strap to tighten it completely around the package.

- Welding: then by creating friction and heat, the two ends of the belt are welded together.

- Cutting: finally removes the excess part of the belt.

All these steps are done in less than a few seconds!

Why do we use a pneumatic strapping machine?

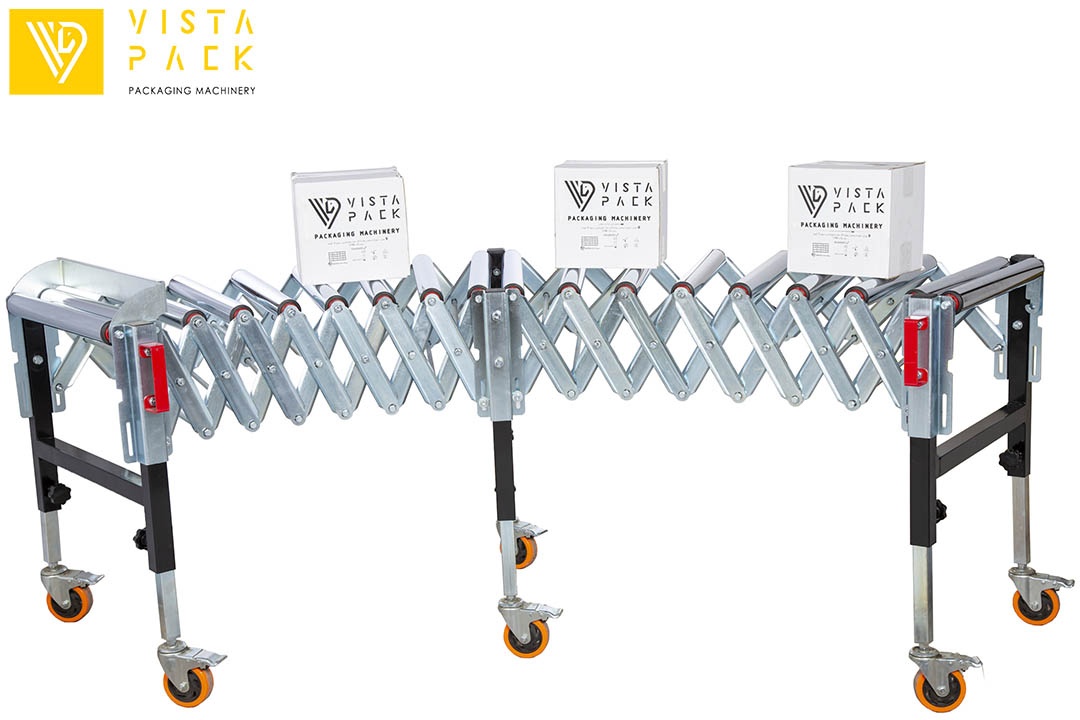

Packing very large or heavy boxes is very difficult because moving them is tiring and time-consuming. With the help of a pneumatic strapping machine device, these products can be easily packed without moving.

In what industries is it used?

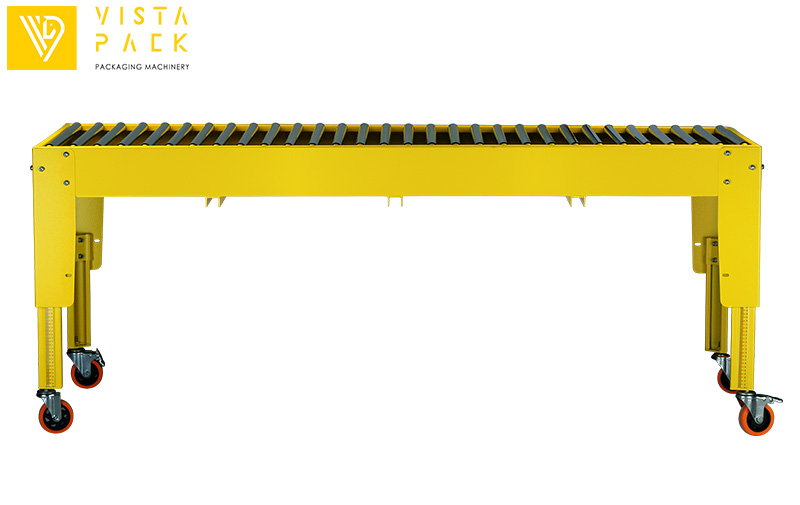

pneumatic strapping machine is very useful for industries with high production volume. Due to the ability to use various belts and the ability to pack different cartons, this device is used in a wide range of the following industries.

- Manufacturing industries and factories

- Warehouses and distribution centers

- Packaging industries

- Transport companies

- Construction industry (for packing materials)

- Wood and metal industries

Important points in using a pneumatic strapping machine

- Correct instruction: Be sure to read the necessary instructions before use.

- Safety equipment: Always wear gloves and safety glasses.

- Regular maintenance: service and maintain the device according to the manufacturer’s instructions.

- Appropriate settings: adjust the air pressure and tension according to the type of package.

- Suitable working environment: use the device in dry and clean environments.

Support and after-sales service of Vista Pack

- One year parts and performance warranty

- 10-year after-sales service

- Technical support and fast supply of spare parts

Buying a manual belt tensioner

When you buy from Vista Pack, you’re not just buying a product – you’re choosing a complete experience of quality and satisfaction. Join our thousands of satisfied customers and feel the difference! To order or get more information, contact us now.

Contact and more information to buy manual belt tensioner

Contact number 00989123798626

Comments and suggestions

dear user🖌 By registering your opinions and suggestions regarding packing machines VISTA PACK ، Help us provide better services.

Reviews

There are no reviews yet.